MueTec offers a comprehensive portfolio of Automated Optical Inspection (AOI) systems tailored for the wafer and photomask industries. Key applications include Critical Dimension (CD) and overlay metrology, defect inspection and review, as well as film thickness measurement. These advanced metrology and inspection solutions are engineered to help semiconductor fabs accelerate development and production ramp-up, maximize die yield, and enhance return on investment.

DaVinci 270UV

MueTec has established a large global installed base of optical Critical Dimension (CD) mask metrology systems. These systems were previously marketed under the “LWM270UV” brand by Leica and KLA. The newest addition to this product line is the DaVinci 270UV—a fully enclosed, fully automated mask metrology system designed for precision and ease of use.

Key Features

- Cost-effective solution for mask layers with feature sizes of 300 nm and larger

- Supports both UV and visible light illumination

- Operates in reflected and transmitted light modes

- Equipped with high-quality optics

- Available in flexible tool configurations

- CD repeatability (3 sigma) over long term < 4 nm for etched layers

DaVinci 200 (CD, OVL, IR)

MueTec’s infrared solutions are engineered to enhance manufacturing yield in MEMS production. These systems are available as fully automated solutions for 100 mm, 150 mm, 200 mm, and 300 mm MEMS wafers.

Key Features

- Best-in-class IR image quality with wavelengths up to 1500 nm

- Flexible wafer handling options including backside vacuum, flipping, and edge vacuum for MEMS-specific substrates

- Support for both reflected and transmitted light illumination modes

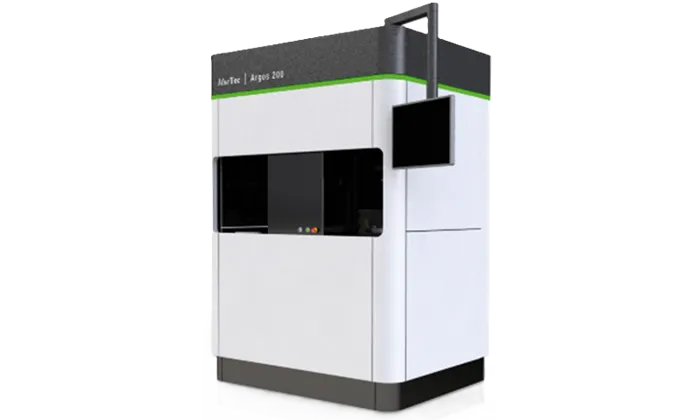

Argos 200

MueTec’s Macro Defect Inspection systems are designed to support a wide variety of wafer types without the need for complex configuration. These systems are user-friendly and require no recipe creation, allowing for seamless operation. Designed to perform 100% inspection during the lithography process, they deliver throughput equal to or faster than typical lithography clusters. This enables customers to transition from sample-based and manual inspections to a fully automated, statistically reliable inspection workflow.

Key Features

- Simultaneous brightfield and darkfield inspection on both frontside and backside of wafers

- Optimized wafer handling system delivering up to 200 wafers per hour

- No recipe required, ensuring ease of use and quick setup