FrontPage-Temporary Bonding & Debonding Equipment (TBDB)

Glass Releasing Layer Coating Equipment-Pyxis RL Series

Scientech, in collaboration with global leader 3M, has developed the Pyxis series Glass Releasing Layer Coating Equipment which provides solutions for glass releasing layer coating in wafer thinning, BGBM (Backside Grinding & Backside Metallization), and advanced semiconductor packaging processes.

Temporary Bonding Equipment-Pyxis TB Series

Scientech, in collaboration with global leader 3M, has developed the Pyxis series Temporary Bonding Equipment, providing solutions for glass bonding processes in wafer thinning and BGBM (Backside Grinding & Backside Metallization). In addition, leveraging its professional in-house equipment development capabilities in the semiconductor field, Scientech has developed temporary bonding equipment applicable to advanced semiconductor packaging processes.

Debonding Equipment -Pyxis FDB & TDB Series

Scientech, in collaboration with international leader 3M, has developed the Pyxis series Debonding Equipment, including Frame Debonding Equipment and Taiko Debonding Equipment, providing solutions for glass debonding processes in wafer thinning and BGBM (Backside Grinding & Backside Metallization).

Debonding Cleaning Equipment

Leveraging its professional in-house equipment development capabilities in the semiconductor field, Scientech has developed the Pyxis series Debonding and Cleaning Equipment, providing solutions for glass and wafer cleaning after debonding in semiconductor wafer thinning processes and advanced packaging processes.

FrontPage-Panel-level Packaging Equipment

Panel-level Packaging Equipment

Batch Panel-level Wet Process Equipment-WSE Panel Series

As semiconductor packaging evolves toward panel-level packaging. Scientech, leveraging its expertise in in-house batch wet process equipment, has successfully developed panel-level batch wet process equipment to meet market demand, applied in panel-level packaging processes. WSE-panel is an advanced and cost-effective panel-level batch wet process system solution, capable of processing multiple panels in a single batch and equipped with multiple tanks suitable for various chemicals.

Single Panel-level Wet Process Equipment-Polar Panel Series

As semiconductor packaging evolves toward panel-level packaging. Scientech, leveraging its expertise in in-house single-wafer wet process equipment, has successfully developed the Polar-panel single-panel wet process equipment to meet market demand, applied in panel-level packaging wet processes.

Single Panel-level Release Layer Coating Equipment-Pyxis Panel Series

As semiconductor packaging evolves toward panel-level packaging. Scientech, leveraging its expertise in in-house single-wafer release layer coating equipment, has successfully developed the Pyxis-panel single-panel release layer coating system to meet market demand, applied in panel-level packaging release layer coating processes.

FrontPage-Wet Process & Baking System

Wet Process & Baking System

Wet Bench Equipment-WS Series

The WS (Wet Station) series is a state-of-the-art, cost-effective wafer processing system solution capable of processing up to 50 wafers in a batch, with multiple tanks suitable for a wide range of chemistries. It supports traditional wet processes such as pre-film clean, etch, post-etch clean, and photoresist stripping. Newly developed features enable batch processing with a smaller footprint, superior productivity, and exceptional cleaning results.

Single Wafer Wet Process Equipment-Polar Series

The Polar series is a single-wafer surface treatment system that leverages FEoL research findings and accumulated expertise in related fields. This system offers exceptional performance and scalability for advanced clean and etch processes, with high throughput and a compact footprint. With industry-recognized reliability and productivity, the company continues to evolve its technology to meet customer requirements and create new advanced cleaning solutions, making it a leading domestic single-wafer wet equipment provider.

Advanced Baking Equipment-Vertabake Series

Vertabake is the most advanced and cost-effective wafer batch baking solution. It can process one batch of wafers (25 wafers) per bake, with the option to bake the batch vertically or horizontally. It is applied in pre-molding baking and pre-underfill baking processes in advanced packaging.

FrontPage-Wafer Reclaim

Wafer Reclaim

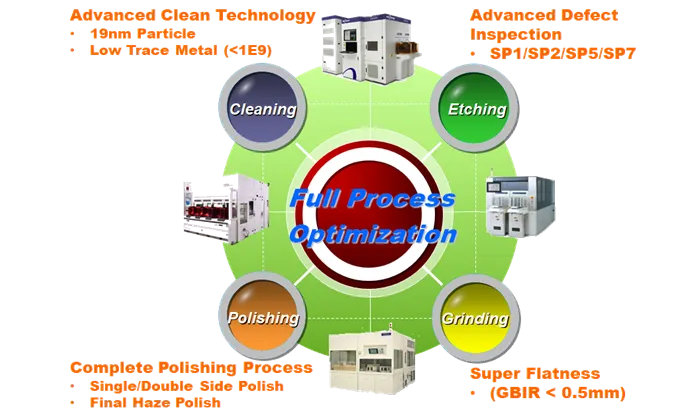

12" Wafer Reclaim

Wafer reclamation involves taking "Test Wafers" or "Dummy Wafers" used in semiconductor manufacturing and processing them through chemical etching, polishing, and cleaning. This removes surface impurities, metals, and oxide layers, restoring them to specifications near those of a "Prime Wafer" so customers can reuse them to reduce costs.

- 12-inch Wafer Reclaim: Applied to mainstream logic and memory advanced processes.

- Advanced Process Support: Maintaining independent production lines for Copper (Cu) and Non-Copper (Non-Cu) processes to prevent cross-contamination.