FlowVIEW leading the Future of Liquid Monitoring: Standardization and Intelligence. Driving the standardization and intelligence of wet process micro-contamination detection, leveraging AI and precise data to simplify processes, stabilize production, and improve efficiency, we aim to become an internationally leading brand in clean technology.

AI Particle Imager S100

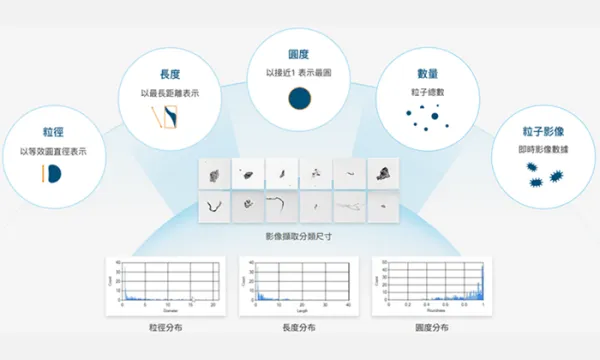

The system provides comprehensive data including particle count, size, length, roundness, and high-resolution images. It further supports AI-based classification algorithms for deep learning, enabling precise identification and categorization of various particle types.

It is ideal for applications such as process contamination monitoring and cleanliness inspection. The system supports a wide range of sample types and delivers real-time classification with statistical reporting.

Features

- Real-time monitoring of nano-scale particle distribution

- Visualization of particle morphology and shape

- High-speed, high-volume, and high-precision particle analysis in fluids

- Five key analytical metrics for comprehensive data insight

- Enhanced AI recognition for classifying hard-to-detect particles with detailed shape and morphology visualization

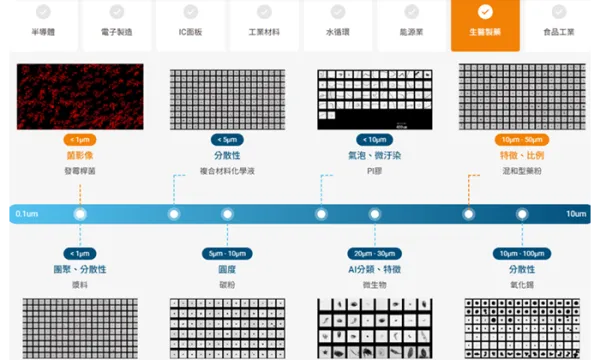

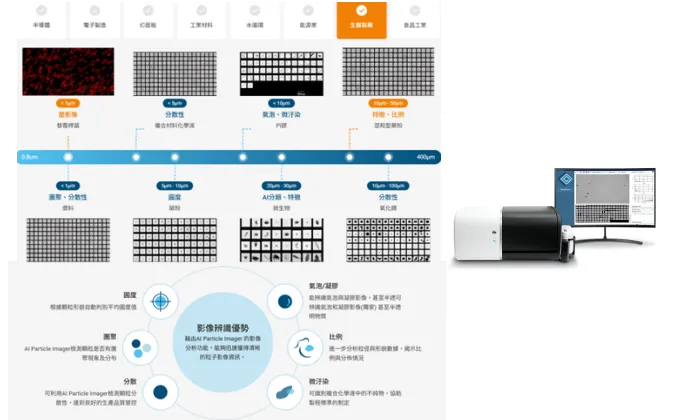

AI Particle Imager S800

Intelligent Fluid Automated Optical Imaging Inspection: Imaging-based fluid optical inspection combines particle size analysis (Sizer) and particle counting (Counter) functions with advanced AI defect detection technology to accurately identify contaminants such as bubbles, crystals, and dust. Seeing is believing, which is the most reliable method and significantly reduces the rate of human error.

Features

- Rapid, high-volume, and precise analysis of particles in fluids

- Image data fully presents particle morphology and appearance

- Precisely counts each particle, ensuring no particle is missed

- Multi-functional image processing and analysis

- AI-powered intelligent feature classification mode (optional)

Multi-channel Liquid Particle Counter (MLPC)

An online wet-process micro-particle automation monitoring solution that provides continuous, long-term particle count monitoring and real-time trend insights across process stages.

Features

- Online 24-hour monitoring of particle counts to capture trends across process stages.

- Establish stable process standards: basis for tool maintenance and process stability; built-in auto data storage for one year.

- One device, multi-point monitoring with 9 detection channels; integrable with existing production tools to lower equipment cost.

- Defect prediction / Auto alarm: threshold-triggered alerts with real-time data feedback; supports preventive maintenance (e.g., filter change) to reduce abnormal-loss cost.

- Compatible liquids: developer, mixed-acid PR remover, copper/aluminum acids, DI water, etc.

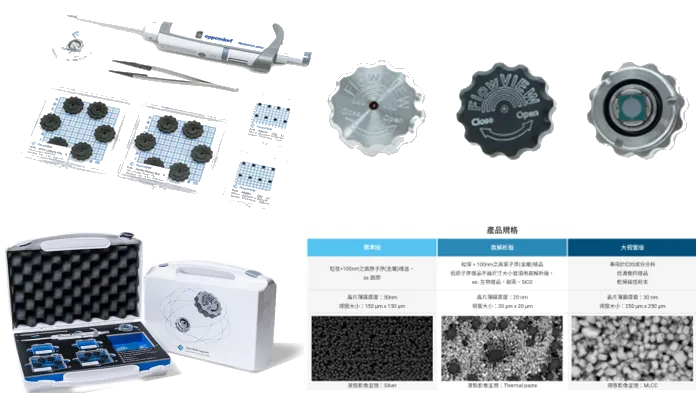

Aquarius Starter Kit

Uses exclusive nano-membrane to create an atmospheric chamber inside the SEM vacuum, preserving the original state of liquid samples without drying. With analysis software, it outputs particle size distribution, dispersion/aggregation, shape, and EDS-assisted composition; highest liquid-phase resolution detects 7 nm particles, streamlining workflows and shortening development time.

Features

- Preserve liquids under SEM with the nano-membrane atmospheric chamber.

- Integrated analysis with FlowVIEW Lite: size distribution, dispersion/aggregation, concentration, shape, composition (with EDS).

- Resolution: liquid-phase detection down to 7 nm.# Compatibility: 99% with major SEM brands/models (FEI, ThermoFisher, Keyence, JEOL, Hitachi, ZEISS, Phenom, TESCAN…) and relevant preparation tools.

- Ease of use: sample sealing in 30 seconds.