January 2025 Newsletter

1. What Does Medical Device Packaging Really Protect?

When most people think about “medical device risk,” their first instinct is: Will it fail? Will it break? In real-world use, however, the most critical concern for patients is infection. Many medical devices (such as catheters, surgical instruments, and implants) are terminally sterilized at the factory and then shipped to warehouses, logistics hubs, and hospitals—only to be opened at the point of use, often in the operating room.

The real challenge is this:

- From the moment sterilization is completed to the second the clinician opens the package

- Months—or even years—may have passed

- The product has gone through transportation, stacking, and temperature/humidity changes

If even a hairline gap forms during this journey—one that is nearly invisible to the naked eye—sterility can be silently compromised. So medical device packaging is not truly about “looking good”; it is about whether sterility can be delivered intact to healthcare professionals at the point of use.

2. Sterile Barrier System + Protective Packaging = A Complete “System”

In international standards, medical device packaging is not just “a pouch”—it is a system:

Sterile Barrier System (SBS)

- Provides a microbial barrier and allows aseptic presentation at the point of use

- Examples: Tyvek®/film pouches, paper/plastic laminate pouches, thermoformed trays with lidding, etc.

Protective Packaging

- An additional outer layer that helps the SBS withstand impacts, stacking loads, and other distribution stresses

- Examples: cartons, shipping boxes, etc.

In other words, a “medical device packaging system” is typically designed and validated as: SBS (inner sterile barrier) + protective packaging (outer protection).

3. ISO 11607, EN 868, MDR: Why Are They Mentioned So Often?

ISO 11607-1 / ISO 11607-2

- The core international standard for packaging of terminally sterilized medical devices

- 11607-1: Specifies requirements for materials, preformed sterile barrier systems, SBS, and packaging systems—how they should be designed and tested

- 11607-2: Specifies requirements for forming, sealing, and assembly processes, including IQ/OQ/PQ process validation

EN 868 Series

In Europe, EN 868 is still used in certain contexts, but many parts have been incorporated into or replaced by ISO 11607. The EN 868 series focuses on detailed requirements for specific sterilization packaging materials (for example, packaging paper and pouches used for ethylene oxide sterilization).

EU MDR 2017/745 (especially Annex I, GSPR)

- The overarching regulation for medical devices in the European Union

- GSPR 11.2: Requires devices to remain sterile under the manufacturer’s specified storage and transport conditions until the sterile barrier system is compromised

- GSPR 13: Requirements for labeling and information supplied with the device, including shelf-life-related information

- GSPR 15: Requirements specifically addressing the manufacture, packaging, and testing of sterile devices

A simple way to remember their roles:

- ISO 11607 & EN 868: tell you how to design and test packaging

- MDR: tells you what level of safety is required to place a product on the market

4. Three Key Questions: From both a practical and audit perspective, medical device packaging ultimately answers three simple questions:

Q1 | At the moment of sealing: Was it sealed properly? Is the seal strong enough? Could it split open during transport? If the seal is too strong, it may tear open abruptly when peeled, causing the device to spring out and compromising aseptic presentation.

Common development-phase tests include:

- Seal Strength (ASTM F88): Cut out the seal area and pull in opposite directions to evaluate peel strength consistency

- Dye Penetration (ASTM F1929, etc.): Apply dye solution along the seal to detect micro-channels

- Burst & Creep (ASTM F1140): Pressurize the package to burst or hold pressure for a defined period to verify how much pressure the structure can withstand

These align with ISO 11607-1 design and integrity requirements—allowing you to demonstrate that “it was sealed correctly from the start.”

Q2 | Over time: Will it still hold up through the end of shelf life?

Medical devices typically have a defined shelf life. That date cannot be arbitrary—it must be supported by scientific evidence. A common approach is Accelerated Aging (ASTM F1980).

- Use elevated temperature to simulate long-term aging

- Perform full integrity and functional testing both before and after aging

- Accelerated aging provides an estimated shelf life, which is later supported by real-time aging data over time

Q3 | After trucks and airplanes: Can it remain sterile after distribution?

In real distribution environments, cartons and trays are treated harshly—dropped, vibrated, stacked, and compressed. Temperature and humidity can also swing significantly during container loading/unloading.

That’s why distribution simulation testing is commonly performed:

- ASTM D4169: Simulates real distribution through sequences of drop, vibration, compression, and environmental cycles

- ISTA 3A: Simulates small-parcel and courier delivery scenarios

After simulation, ASTM F88/F1929/F1140 and other methods are used again to confirm: “After this ‘rough ride,’ did the seals or packaging develop any new leaks or damage?”

5. Taking It Further: Not Only Physical Integrity, but Also Microbial Barrier Performance

ASTM F88, F1929, F1140, F1980, and D4169 primarily evaluate physical integrity: Will it break? Will it leak? Will materials degrade? For certain higher-risk products, the next step is microbial barrier testing (for example, ASTM F1608 / DIN 58953-6). This uses live microorganisms to verify the packaging material’s microbial barrier performance—confirming that, under defined conditions and time, bacteria will not penetrate into the package. This enables you to demonstrate not only “the package is intact,” but also “the material itself provides adequate microbial barrier protection.”

6. Conclusion: Treat “Sterility” as the Real Product

To clinicians and patients, it looks like a catheter, a clamp, or an implant. From a safety perspective, what you are truly delivering is a complete sterile system—validated by design, process qualification, and long-term storage and distribution verification. Packaging is the final, yet critical, link in that system.

| Your Need | Related Tests & Standards | Recommended Instrument Types |

|---|---|---|

| I want to monitor oxygen changes inside the package to confirm seal and barrier stability |

|

|

| I need to verify seal strength and consistency to support ISO 11607-1 design validation and sealing OQ/PQ |

|

|

| I need to demonstrate the package will not burst or slowly leak under pressure (burst/creep compliance) |

|

|

| I want leak testing to find invisible leak paths for integrity validation and in-process sampling |

|

|

| I need to establish shelf life and demonstrate sterility is maintained through the labeled expiry date |

|

|

| I need to simulate distribution (drop, vibration, compression) to ensure packaging is not compromised during shipping |

|

|

| I want to address ESG/sustainability and evaluate the biodegradability of packaging materials |

|

|

Related Products

ECHO

ECHO Instruments is a global analytical instrumentation company with over 30 years of experience, dedicated to making the world a better and cleaner place. As a worldwide leader in automatic respirometric systems, ECHO provides advanced solutions for environmental biodegradation and compostability testing, wastewater and soil research, as well as optical oxygen analysis for pharmaceutical and modified atmosphere packaging applications.

A system that measures CO₂ production (and O₂/CO₂ concentration in the flow) during biodegradation under controlled conditions; continuously monitors flow, temperature, pressure, humidity; software calculates CO₂ production and % biodegradation; additional gases can be measured.

Features

- Modular & upgradable; optional gas sensors (e.g., CH₄, H₂S, H₂, NH₃)

- Aerobic or anaerobic; temperature range about +3°C to +70°C

- Multi-channel (12/24/36/48/60); MFC per channel

- Plug & Play; compressor included; auto humidification; leakage alarm; remote control; Excel export

- Optional on-line δ¹³C isotope integration

- Biodegradation testing in composting / soil / seawater / freshwater / wastewater /sediment /activated sludge /algal environments

- Biodegradation measurement of organic waste, plastics and biotechnology R&D, food respiration

- Respiration measurement of insects and small animals

- Online δ¹³C isotope analysis integration, etc.

ISO 14855-1, ASTM D5338; ISO 17556; ASTM D6691; ISO 14852; OECD 301B

Measures O₂ to determine microbial activity in degradable organic matter under defined continuous airflow and adiabatic conditions; sealed adiabatic vessels create conditions defined by EU and other norms.

Features

- 1/3/6/12 channels; Plug & Play; temperature sensor in each vessel; automatic condensate removal

- Measures temperature/flow/pressure/humidity; O₂ range 0–25% (accuracy stated 2%)

- Multiple vessel sizes; remote desktop control; compressor included; Excel

Waste degradation and biological stability testing using DRI; other waste degradation applications

- UNI 11184

- EN 15590

Portable/automatic analyzers for simultaneous gas flux measurements (CO₂, O₂, CH₄ and others on request) over a wide dynamic range on various surfaces; suitable for fields, forests, landfills, etc.

Features

- Portable or stationary (automated); lightweight

- Built-in GPS for map positioning

- Compatible with up to 5 different gas sensors (different ranges)

- Operable on tablets/phones/PCs; software allows for on-site flux calculation.

CO₂ flux from soil/compost/landfills; pollution spill identification; agronomy; post-fire activity; uranium mines mapping; carbon fingerprint & greenhouse gases; playground gas presence

Determines the degree of disintegration of plastics under defined composting conditions in a pilot-scale test.

Features

- Single/Multi-channel: 1/3/6/12; Plug & Play

- Control unit integrated with PC; each reactor has a cooling system

- Measures temperature and flow rate; O2 measurement range 0–25% (accuracy indicated 2%)

- Multiple container sizes; remote desktop control; includes air pump/compressor; Excel export

- Pilot-scale disintegration test in the "Industrial compostability" assessment process for plastic materials according to ISO 16929

- ISO 16929

Compact respirometer for screening & R&D; can connect to existing hardware (stand-alone controller) or be delivered as a complete setup.

Features

- Configuration

- Stand-alone controller compatible with existing containers/boxes, etc.

- Complete package in one go (container, incubator, gas source, PC)

- Modular and upgradeable; new software features; multiple mixing options

- Advantages (Performance/Operation)

- Multi-channel: 6 / 12 / 18 / 24 / 30 / 36…

- Plug & Play; suitable for screening and R&D

- Measures O2, CO2, temperature, flow rate, pressure, humidity; multiple gas sensors with various ranges

- Remote desktop control; Excel export

- Biotechnology & microbiology (fermentation, pathogen respiration/antibiotic resistance, microbial growth)

- Environmental science & agriculture (soil/plant respiration, pesticide/fertilizer impact, biofilm indication, biomass/biofuels)

- General lab respiration experiment

Fully automatic optical O₂ analyzer for determining O₂ concentration in blister packs and other MAP pharmaceutical packaging for QC and production lines; measures 1–6 blisters at once, up to 72 points in one serial measurement.

Features

- Headspace measurement, no sample extraction required

- High precision, no O₂ consumption during measurement

- Automatic calibration

- Supports IQ/OQ files (verification files)

- Complies with 21 CFR Part 11 (requirements related to data integrity/electronic records and signatures)

- O₂ concentration in blister packs (1–6 blisters at once; up to 72 points per serial measurement).

- 21 CFR Part 11

- Industry 5.0

Portable device for O₂ concentration in headspace of various MAP packaging; micro-invasive measurements enabled by <140 µm optical sensor tips; compliant with pharmaceutical standards and 21 CFR Part 11.

Features

- Measurable in gas or liquid phases

- No sampling or extraction required, high precision, measurement without O₂ consumption

- Supports salinity factor input for different salinity samples (vial)

- IQ/OQ files; provides 2 sterilizable sensors

- Quick calibration, user-manageable

- Battery or AC power powered

- Pharmaceuticals: O₂ concentration in blister packs, vials, tubes, patches, resealable bags, and other packaging.

- Food and Beverages: O₂ concentration in coffee, meat products, dairy products, and various MAP packaging.

- Science: Biotechnology, micro-respirometry, marine research, and R&D.

- 21 CFR Part 11

INDUSTRIAL PHYSICS

工業物理,我們為世界各地的製造商、生產線和實驗室確保包裝、產品和材料的完整性。我們在廣泛的專業應用中提供一流的測試和檢測解決方案。工業物理提供近 100 年的經驗、廣泛的設備組合以及將您的需求放在首位的全球服務。

材料測試 | 柔性包裝檢測 | 氣體及包裝密封檢測 | 鍍層-塗料-塗層測試 | 飲料罐裝檢測

Systech Illinois成立於1983年,是一家來自英國,專為氣體測量提供品質控制設備的製造商,有近30年的感測器研發、生產和應用經驗,是全球微量氧和微量水檢測領域的技術和品質的領導者。Systech Illinois總部位於英國牛津,同時在美國和瑞士各擁有一個分工廠 Illinois Instruments,並在全球50多個國家和地區設銷售網路。

特點

- 7101水蒸氣透過率分析儀

- GS 6000 頂空氣體分析儀

- Lyssy L80-6000水蒸氣透過率分析儀

- GS Micro 微量頂空氣體分析儀

- 8101e 氧氣透過率分析儀

- MM500 微量水分析儀

- EC900 線上微量氧分析儀

- EC92D/IS 防爆認證便攜微量氧分析儀

- PM700 機械順磁氧分析儀

- EC9031 缺氧監測儀

- EC91 防爆認證微量氧分析儀

產品規格

產品廣泛應用在包裝材料,食品,製藥,化工,鋼鐵,石化,電子,氣體製造,航空航太等行業。

Systech Illinois的主要客戶涵蓋食品藥品及汽車工業,鋼鐵,電子等行業領域,包括Tulip包裝肉、WHITWORTHS衛芙、控之星、聖培露礦泉水、坎普登食品研究院、德尼培集團、波士頓科學、百特醫療集團等。

- ASTM F 3299-18; ASTM F1249; ISO 15106-3; DIN 53122-2

- ASTM E398; ISO/CD 15106; JIS K 7129; TAPPI T523 om-82; NF H00-044

- ASTM D 3985; ASTM F 1927; ASTM F 1307; DIN 53380-3; JIS 7126; ISO CD 15105-2; GB/T 19789

TM Electronics, Inc成立於1961年,是一家來自美國,測量包裝完整性,致力於生產先進且自動化的實驗室儀器設備製造商。產品包括檢漏儀、流量測試儀、壓力衰減儀、真空檢漏儀等專業檢漏設備。TME作為包裝完整性設備的世界領先者,服務於醫療、塑膠、包裝薄膜、食品、醫藥、電子和汽車工業等諸多行業的需要。

特點

- Worker Integra 檢漏儀

- 定制化夾具

- BT Integra Pack 檢漏儀

- Solution 密封性測試儀

- Integra Flex 檢漏儀

產品規格

TME的主要客戶分佈于食品藥品、電子及工業領域。包括雅培實驗室、百特醫療集團、強生、波士頓科學、羅克韋爾自動化、美國伊頓、摩托羅拉、富士康、偉創力、福特汽車等。

- ASTM F-2054; ASTM F-1140; ASTM F-2095; ISO-11607 FDA CFR 21 Part 11

Eagle Vision創立於1995年,總部位於荷蘭,是全球知名的線上機器智慧視覺檢測系統方案供應商。產品類型廣泛,包括金屬罐360°檢測、空罐檢測、罐外360°全檢及空瓶瑕疵檢測。Eagle Vision模組化的設計,既能滿足客戶當前檢測需求,又允許客戶添加其他檢測專案。

特點

- 360罐子視覺檢測系統

- 噴碼視覺檢測系統

- 瓶蓋視覺檢測系統

- 空罐檢測系統

產品規格

Eagle Vision主要應用於食品,飲料和包裝行業,同時也廣泛應用于嬰幼兒奶粉罐及糖果市場。Eagle Vision的主要客戶包括雀巢、達能、荷蘭皇家菲仕蘭、伊利、雅士利、愛氏晨曦、喜力、青島啤酒、哈裡波軟糖、億滋、皇冠、利合泰科技等。

標準規範

CMC-KUHNKE成立於1971 年,工廠位於德國首都柏林,是一家金屬容器檢測儀器的專業研發製造廠商。CMC-KUHNKE一直是行業創新的引導者,先後發明電腦化卷封檢測、2片罐自動測量、無損卷封檢測及卷封緊密度測量技術。

特點

|

|

產品規格

近50年來,CMC-KUHNKE 業務遍佈全球,產品覆蓋食品罐、飲料罐、氣霧罐及罐蓋檢測,以其多年的經驗及先進技術,為世界各地的金屬罐生產商、飲料及罐裝食品生產商和罐裝廠商提供高可靠的檢測方案及服務。CMC-KUHNKE的主要客戶包括可口可樂、百事可樂、雀巢、麒麟、皇冠、Ardagh Group、蘇德羅尼克等。

- GBT 2520-2000; G3303-2002

United Testing Systems于1964年成立,總部位於美國,是世界一流的電子萬能材料試驗機、多工位元拉伸試驗系統和液壓萬能試驗機製造商之一。UTS有超過50年的試驗機研發和製造歷史,開創了第一個自動資料獲取和還原系統,能夠在不需要操作員參與的情況下連續測試多個樣品。這些突破使UTS 建立和保持了自己在材料測試技術領域的領先地位。

特點

- 臺式 DTM/ 落地式 DFM 電子萬能材料試驗機

- DHFM液壓萬能材料試驗機

- LCH Speedy 現場快速試驗機

- TruBlue II 洛氏硬度計

- Tru Blue μVT 顯微硬度測試系統

- Tru Blue 樣品切割機

- Tru Blue 樣品鑲嵌機

- Tru Blue 研磨拋光機

- 夾具及附件

- 環境試驗倉

- 引伸計

產品規格

UTS產品廣泛應用於汽車,航太,土木工程,建築,電子,醫藥,包裝,塑膠,紡織,複合材料,高等院校研究所等行業。UTS在全球範圍內擁有廣泛的銷售和服務網路,主要客戶涵蓋金屬包裝、柔性材料、汽車、航空、緊固件、建築、塑膠及橡膠製造業等多個行業領域,包括PPG塗料、陶氏、福特汽車、通用汽車、耐世特汽車、天納克、波音等。

- ASTM E8; ASTM D412; ASTM D638; ASTM D695; ASTM D1002; ASTM D1876

- ASTM E18; ISO 6508

- ASTM E384; ASTM E92; ISO 6507; ISO 9385; ISO 4546 * 也可能符合其他未列出的標準

- ISO 527; ASTM D638; ASTM E8; ISO 6892; ASTM D3039; ASTM D412; ISO 37; ASTM D882

Ray-Ran成立於1977年,總部位於英國伯明罕,專門為聚合物工業應用的使用者提供加工測試設備,被視為高分子行業測試設備的主要供應商之一。與全球大多數其他測試設備製造商相比,Ray-Ran可以提供更廣泛的產品範圍,涵蓋了原材料測試,樣品製備,樣品測試等全面的測試要求。Ray-Ran 始終保持其核心業務活動的強大工程和製造基礎,提供40多種不同的產品。主要產品包括密度梯度儀,擺錘衝擊儀,熱變形和維卡軟化點測試儀等。目前,Ray-Ran在39個國家/地區設有本地分銷商和代理商,使用者遍佈60多個國家和地區,獲得了良好的口碑。

特點

- PCP 氣動樣品沖切機

- CNC 樣品數控銑床

- MFR300 熔融指數儀

- DGA 自動密度梯度儀

- HDV熱變形/維卡軟化點六位測試儀

- IMT 擺錘衝擊試驗機

- 儀器化落錘衝擊試驗機

- FDT 落鏢衝擊試驗機

- X100 臺式萬能材料試驗機

- X250 單立柱臺式萬能材料試驗機

- X500雙柱高力值萬能試驗機

- X350雙柱臺式萬能試驗機

產品規格

Ray-Ran 的主要客戶涵蓋電子、軟硬包裝、油氣化工、醫療器械、建築、汽車、航空航太、化學原料等領域,包括三星、LG、施耐德、印度瑞來斯、James Walker、陶氏、薩索爾、畢瑪時、捷豹路虎、起亞、米其林、威文集團、埃克森美孚、中國石化等。

- ASTM D7136

- ASTM D3763-02

- ISO 6603

SpecMetrix®高級實驗室塗層厚度測量系統為使用者提供了高標準的非接觸、非破壞性和即時塗層及樣品塗層厚度測量。SpecMetrix精確和創新的ROI增強光學干涉技術,使用者可以獲得樣品的完整塗層測量資料。允許您通過非接觸和非破壞性手段獲得塗層測量。

- 測量範圍: 0.7至350微米

- 精度: 塗層厚度的±3%

- 測量速度: 每秒最多150次

- 掃描速度: 最高5英寸(125毫米)/秒

- 濕塗層或乾塗層

- 清晰、著色或有色塗層

- 適用於任何基材的塗層,幾乎適合任何行業,包括柔性包裝、汽車和工業

- 廣泛應用 – 即時測量單層或雙層塗層,或亞微米級的離散層

- 模組化設計,具有從品質控制實驗室到生產車間的即時測量能力

標準規範

如果您使用金屬包裝,那麼 Quality by Vision (QBV) 擁有可靠的檢測機器來檢查一切是否正常。無論您是罐頭製造商、罐頭灌裝機還是供應商,我們都擁有質量和流程控制系統,讓您的生活更輕鬆。

特點

- Buckle & Burst Tester: 氣溶膠罐

- 罐身塞徑規

- ENR-4000 數字搪瓷評估器

- MDA – 氣霧罐多維自動測量儀

- MDE – 氣溶膠端的多維自動測量儀

- 板厚儀

- QVIS-A1:氣溶膠的 100% 視覺檢測

- 分數殘留量規 - 氣溶膠

- SEAMetal HD:氣霧罐

- TBS-LSS:縫鋸、氣霧罐

產品規格

- 氣溶膠測試、飲料測試、爆破測試、罐頭檢測、塗層測試、樣品測試、強度測試

- 汽車行業、飲料行業、食品行業、工業行業、金屬包裝

標準規範

幾十年來,C&W Specialist專業設備一直在製造旨在提供現代工業要求的嚴格環境測試的機械。C&W Specialist現在在汽車製造的所有主要部門以及油漆、表面和塗料、化學、電子、航空航天、軍事和海上工業中都受到依賴。

特點

- C&W 鹽霧腐蝕試驗箱

- 鹽霧冷凝箱

- 濕度調節櫃

- 濕度櫃

- 鹽霧櫃

產品規格

- 腐蝕測試、油漆測試

- 航天行業、汽車行業、建築與土木工程、防禦、工業、油墨和塗料行業

- ASTM B117 標準的鹽溶液

Steinfurth 產品線提供最高質量的機電測量測試儀器——讓您保護包裝、產品和材料的完整性。為飲料、食品和製藥行業的製造商提供創新的測試和檢測解決方案。提供二氧化碳測量儀器、記錄儀系統、碳酸化系統、實驗室搖床、分析儀器或包裝測試設備。

特點

- NICO 是市場上唯一的非侵入性手持式 CO2 分析解決方案。這是全球首創 - 提供了一種非破壞性方法來測量灌裝飲料容器中的 CO2。

- CO2範圍:0-10 vol / 0-20g/L

- CO2準確度< 2%

- CO2重複性< 1.2%

- 壓力範圍:14-87 PSI

- 壓力精度< 1.5%

- 壓力重複性< 0.5%

- 溫度:5 – 35 °C

- 溫度精度/重複性< 0.25%

- 測量時間< 15 s

- 尺寸:160 x 220 x 110(高 x 寬 x 深)

- 重量:1200g(含電池)

- 雷射等級:1M

- 應用:飲料測試, 氣體分析和測試

- 行業:飲料, 軟包裝, 食物, 金屬包裝, 製藥

- 材料:氣體

標準規範

Büchel公司于1924年在荷蘭成立,主營紙張表面性能的測試設備,其合作開發的Bekk平滑度和PPS印刷粗糙度至今還是行業標準。1982年Büchel並購英國公司Messmer,並改名為Messmer Büchel。Messmer Büchel是包材(尤其是紙張物性)實驗室儀器設備的知名供應商,目前公司已擴大到為其他行業如包裝,印刷品質控制,紡織材料和塑膠薄膜提供測試設備。

- 13-56 破裂度儀

- 49-56 厚度測試儀

- 58-05 BEKK平滑度測試儀

- 58-06 PPS粗糙度儀

- 58-27 本特生粗糙度測試儀

- 79-15 折痕挺度測試儀

- 79-56 彎曲挺度測試儀

應用領域包括撕裂度測試儀、厚度測試儀、平滑度儀等。Messmer Büchel在全球範圍內擁有廣泛的銷售和服務網路,主要客戶涵蓋造紙、軟包裝、煙草、石油行業等,包括3M、Printpack、陶氏、台塑企業、畢瑪時、艾利丹尼森、沙伯基礎、國際紙業、金光紙業等。

- ISO 2758; ISO 2759; ASTM D 3786; ISO 1328-2:1999; ISO 2960; BS 4768;

- TAPPI T403 紙張耐破強度; TAPPI T807 紙板和掛麵紙板耐破強度; TAPPI T810 瓦楞紙和實心纖維板耐破強度

- ASTM D374、D1777、D5729、D6988;ISO 534、3034、4593:1993、5084、9073-2、12625-3 APPITA 1301.426;TAPPI T-411;EDANA 30.4;PAPTAC D.4;DIN 53370;BS 2782-6;WSP 120.1/6

- ISO 5627; TAPPI T-479; DIN 53107

- GB/T 2679; ISO 8791; TAPPI T555

- 粗糙度:ISO 8791-2; Scan P21; Nen 2012; BS 4420; DIN 53108

- 透氣度:ISO 5636-3; Nen 2015; BS 1990; DIN 53120

Testing Machines, Inc 於1917年在美國紐約成立,在1931年開始業務轉為向美國造紙工業實驗室提供檢測儀器。多年來,TMI 作為實驗室儀器供應商把業務擴張到範圍更廣的行業,包括塑膠、紡織、粘合劑和橡膠。TMI 銷售辦事處和代理網路遍佈全球超過50個國家,能為全球客戶提供服務和校準。

- 32-76e 摩擦係數儀

- 80-91 剝離測試儀

- 43-76 擺錘衝擊儀

- 83-76 撕裂度儀

- 80-20 內結合強度儀

- 75-50 SL 10 熱封熱粘儀

- 75-59 TS 4 熱封儀

- 10-20 油墨摩擦儀

主營產品包括摩擦係數儀、撕裂度儀、熱封熱粘儀、油墨摩擦儀等。 TMI 的客戶包括紙張、塑膠薄膜、瓦楞包裝紙板、包裝產品、塑膠、標籤、膠粘劑和其他各種材料和消費產品廠商,國際知名客戶主要包括3M、Printpack、陶氏、台塑企業、畢瑪時、艾利丹尼森、沙伯基礎、國際紙業、金光紙業、埃克森美孚、中國石化等。

- 摩擦係數符合:ASTM D 1894; ISO 8295; TAPPI T 549

- 剝離係數符合:ASTM D 1876; ASTM F 88; ASTM D 3330 PSTC-101; FINAT1

- ASTM D 3330; TLMI L-IA1 & L-IA2; PSTC-1, 3, 4; FINAT FTM 1, 2, 3, 4

- 針對IZOD的ASTM D256和ISO 180

- 針對Charpy 的ASTM D6110和ISO 179

- 針對碎片衝擊測試的ASTM D4508

- 針對無缺口懸臂梁的ASTM D4812

- TAPPI T-414; ASTM D1922; ASTM D1424; ASTM D689

- ISO 1974; CPPA d.9; AS/NZ 1301.400S; BS 4468; SCAN P-11

- QB/T 2358(ZBY 28004); ASTM F2029; ASTM F 1921; YBB00122003-2015; YYT 1433

- ASTM D 5264; TAPPI T-830; ASTM F-1571; FINAT FTM 27; ASTM F 2497

SpecMetrix® ACS 系統是先進、精確的塗層厚度和塗層重量測量系統,專為金屬包裝容器設計。該系統在塗層金屬罐製造商和支援它們的塗料供應商中有廣泛的應用,尤其適用於罐體的內部和外部塗層的測量。SpecMetrix® ACS 系統根據您的罐廠需求進行配置。我們提供從靈活的單罐測量型號,到適用於多罐測量的生產車間半自動非接觸解決方案,能夠提供高度精確的塗層重量資料,支援您的程式控制、品質保證或索賠審核。

- 單罐:ACS-1系統可測量單個罐體的塗層,使用90°或靈活角度探頭,非常適合容器品質保證、研發和塗料供應商使用

- 多罐:ACS-10系統為生產團隊提供了在實驗室中批量測量1到10個罐體的靈活性,也可在生產車間環境中進行測試

- 單罐或多罐

- 內外塗層測量

- 適用於任何金屬基材(鋁、鋼、鍍錫板);適用於任何印刷表面、印刷或底色,包括黑色

- 靈活和可擴展,以滿足您的需求

- 可根據工廠需求進行自動化配置和升級

標準規範

SpecMetrix 提供獨家的線上塗層厚度測量系統,適用於塗層和生產線。這些系統旨在提供應用塗層的非接觸、非破壞性和即時厚度測量。SpecMetrix®線上塗層測量系統具有極高的適應性。不論您的塗覆基材為何,我們都可以為您的濕塗或乾塗工藝控制與品質保障需求,提供合適的塗層與膜厚測量解決方案。

- 測量範圍: 0.7至350微米

- 精度: 塗層厚度的±3%

- 測量速度: 每秒最多150次

- 掃描速度: 最高5英寸(125毫米)/秒

- 精確測量塗覆、處理或覆膜卷材的塗層厚度

- 可測量濕膜或幹膜,厚度精確至亞微米級

- 適用於透明、彩色或著色塗層厚度測量

- 可測量各種金屬基材上的塗層,包括鋁、鋼、馬口鐵、冷軋鋼、鍍鋁鋅等,無論基材上噴塗何種底色

- 即時測量預處理、底漆、面漆、罩光漆、背塗層、覆膜、清漆等各種卷材塗層

標準規範

OxySense成立於上世紀80年代,總部位於美國,是光學氧氣測量系統領導者,主營包裝和加工行業的光學氧氣感測器系統,其創新的光學傳感系統可在許多世界先進的公司的研究實驗室和生產車間中找到。OxySense實驗室系統為滲透測試 (薄膜包裝和成品包裝)、貨架壽命研究、頂空分析、溶解氧研究及封閉表徵提供了一套完整的解決方案。

特點

OxySense的主要客戶涵蓋食品、飲料、包裝、製藥和生物醫學領域,包括可口可樂、雀巢、金寶湯、安姆科、日本可樂麗、美國莊臣等。

產品規格

- 薄膜、瓶及包裝等氧氣透過率分析

- 頂空氧及溶解氧分析測試

- 保質期研究

- 密封性測試及洩露檢測

- 去氧劑性能分析與評價

- 生產線上分析監控

- 厭氧環境監控

- ASTM 標準 F2714-08 和 ASTM F3136-15

SYSTECH ILLINOIS

Systech Illinois offers advanced testing systems for oxygen, gas, and moisture analysis. Designed in compliance with industry standards, these instruments address critical analysis needs across various applications. Our high-performance headspace and permeation analyzers ensure packaging integrity in industries such as plastics, food, pharmaceuticals, and medical devices—delivering accurate, repeatable results you can rely on.

Brought to you by Systech Illinois, the world-leading brand in gas, oxygen, and moisture analysis, the EC900 series oxygen analyzers deliver fast, accurate measurements—detecting oxygen levels as low as 20 ppm from ambient air within two minutes.

These advanced instruments feature user-friendly software and high-quality sensors for reliable, repeatable results. Designed for use in a wide range of industrial gases and environments, EC900 analyzers are unaffected by hydrocarbons or volatile compounds—making them ideal for wave soldering, reflow ovens, and more. With multiple sensor options, the EC900 series offers a solution to fit every measurement need.

Key Features

- Long-life, maintenance-free disposable oxygen sensor

- Robust construction with three sensor configuration options

- Calibration via ambient air or certified gas

- Microprocessor-controlled operation

- Large, autoranging LED display

- Fast response time

- Vibration-resistant design

- Includes warranty coverage

Model Variants

EC920 Oxygen Analyzer

Weatherproof and waterproof with NEMA 4X / IP66 protection. Ideal for harsh industrial environments.

- Weight: 15.5 kg

- Dimensions: 380 mm (W) × 160 mm (D) × 460 mm (H)

EC930 Oxygen Analyzer

Supplied with a 19-inch rack mount, suitable for housing one or two analyzers in a compact footprint.

- Weight: 9.7 kg

- Dimensions: 484 mm (W) × 410 mm (D) × 190 mm (H)

EC910 Oxygen Analyzer

Versatile design for panel mounting or benchtop use—ideal for lab and integration applications.

- Weight: 7.9 kg

- Dimensions: 237 mm (W) × 410 mm (D) × 190 mm (H)

- Industrial gas monitoring

- Glove boxes

- Oxygen-controlled atmospheres

The Gaspace Advance Micro is a headspace gas analyzer designed for oxygen (O₂) and carbon dioxide (CO₂) measurement, ideal for the food and pharmaceutical industries. With automatic calibration, diagnostics, and control features, it delivers consistent, accurate results—critical for HACCP compliance.

Key Features

- Analyzes headspace volumes as low as 1 mL

- User-friendly touchscreen interface

- Five configurable test methods

- Automatic calibration and self-diagnostics

- Customizable pass/fail criteria

- Built-in printer for results

- Documentation support for IQ, OQ, and PQ

- 21 CFR Part 11 compliant

- Measurement range:Oxygen 0.001%-99.9%;CO2 0.1%-99.9%

- Response time:3s

- Sensor Type:Zirconia & Dual wavelength, Infra-red

- Minimum volume of sample gas:1ml

- Pharmaceutical vials

- Fish

- Pharmaceutical packaging

- Wine

- Fresh meat and cooked meat

- Vegetable salads

- Snack foods

- Ready meals

- Coffee pods

The 7101 water vapor analyzer range uses a sensitive and stable P₂O₅ sensor for absolute moisture measurement. With a wide detection range of 0.002–1000 g/m²/day and precise control of temperature, humidity, and flow, it delivers accurate, repeatable WVTR (Water Vapor Transmission Rate) results for both R&D and quality control of packaging films.

Key Features

- Cost-effective, user-replaceable sensor

- Long sensor lifespan with low replacement cost

- Runs on a full Windows® OS for secure operation and network connectivity

- Anti-surge function protects sensor from high moisture levels

- Validation completed in hours using third-party certified, NIST-traceable gases

- Remote diagnostics and support available (with user permission), reducing service downtime

- Gas: Water vapor

- Application: Permeation

- Measurement range: 0.002 to 70 g/(m²·day); up to 1,000 g/(m²·day) when masked

- Test temperature range: 10 to 40 °C (50 to 104 °F)

- Test relative humidity (RH) range: 20% to 90% RH

- Sample size: 50 cm² (adapters available for smaller samples)

Applications

- Permeation testing

Industries

- Flexible packaging

- Food

- Pharmaceutical

- ASTM F 1249

- ASTM F3299-18

- DIN 53122-2

- ISO 15105-2

- ISO 15106-3

The L80 series analyzers have been trusted by laboratories worldwide for decades. The L80-6000 represents the latest generation, offering a reliable testing principle, minimal maintenance, and excellent cost-efficiency. Designed for testing high-permeability materials with specialized sample cards, it delivers rapid and accurate results—the higher the permeability, the faster the test time. Along with a broad measurement range, it ensures high precision and ease of use.

Key Features

- User-friendly operator interface

- Highly automated for simple operation

- Fast and accurate test results

- Wide testing range for both low and high permeability materials

- Automatic equilibrium detection

- Automatic temperature control

- Easy setup of test parameters and sample data

- Convenient test sample holders

- Built-in printer for test documentation

- Low maintenance requirements

- Gas: Water vapor

- Application: Permeation

- Measurement range: 0.03 – 10,000 g/m²/day

- Test temperature range: 5 to 50 °C (41 to 158 °F), with built-in temperature control

- Test humidity: 5% to 60% RH

- Ambient humidity: 10% to 90% RH (non-condensing)

- Dimensions: 400 × 400 × 350 mm

- Weight: Approximately 24 kg

Applications

- Permeation testing

Industries

- Beverage

- Flexible packaging

- Food

- Inks & coatings

- Paper & pulp

- ASTM E398-3

The OxySense 8101e is an expandable oxygen transmission rate (OTR) analyzer designed to reduce testing costs. As the only major provider offering satellite expansion, Systech Illinois allows labs to scale efficiently by adding capacity as needed—lowering cost per test while maintaining precision and reliability.

Key Features

- Completely redesigned system

- High-sensitivity, wide-range eMetric™ coulometric sensor

- Easy operation—load the film and press start

- Windows-based control software with Quickstart configuration and clear results display

- Q-Seal™ gas-free film loading system

- Automatic control of relative humidity and temperature

- “Test Condition Matrix” (TCM™) enables multi-condition testing (up to 10 conditions) with one click

- Expandable system—supports up to 32 test cells

- Gas: Oxygen

- Application: Permeation

- Controlled RH testing (films): Carrier and test gas

- Controlled RH testing (packages): Ambient or chamber-controlled

- Test temperature range: 10 °C to 40 °C ± 0.1 °C

Applications

- Permeation testing

Industries

- Beverage

- Flexible packaging

- Food

- Inks & coatings

- Paper & pulp

- ASTM D3985

- ASTM F1307

- ASTM F1927

- DIN 533803-3

- ISO CD 15105-2

- JIS 7126

The Gaspace 6000 headspace analyzers combine advanced technology with user-friendly operation to meet the industry's highest standards for accuracy and reliability. These systems feature built-in sampling, durable zirconia and infrared sensors, and microprocessor control to ensure consistent, repeatable results.

Key Features

- Simple setup and operation

- AccuFlow transducer for precise flow control

- Intuitive menu interface

- One-touch calibration

- Customizable pass/fail testing

- Lightweight and portable design

- USB port for diagnostic software

- Optional external printer via RS232

- Can piercing station

- 45° adaptor for can piercing

- Waterproof protective case

- Syringe injection port capability

- Gas: Oxygen, Carbon Dioxide

- Application: Gas flushing of food, headspace analysis

- Oxygen range: Autoranging from 0.001% to 100% (models GS6500 & GS6600)

- Carbon dioxide range: Autoranging from 0.1% to 100% (models GS6600 & GS6700)

- Response time: Less than 5 seconds (O₂), less than 10 seconds (CO₂)

- Weight: 4 kg (9 lbs)

- Dimensions: 305 W × 254 D × 152 H mm (13.5 W × 11.5 D × 5.7 H inches)

- Can piercing station: For analysis of rigid cans and jars

Applications

- Gas analysis and testing

- Oxygen headspace testing

Industries

- Beverage

- Flexible packaging

- Food

The PM700 delivers best-in-class high-performance oxygen analysis. This advanced paramagnetic analyzer features intuitive software for accurate and reliable results. With an autoranging capability from 0.01% to 99.99%, it is ideal for oxygen purity measurements. Its non-depleting sensor ensures long-term, maintenance-free operation.

Key Features

- Paramagnetic sensor with PID temperature control for superior accuracy

- Optional barometric pressure compensation for enhanced purity analysis

- Auto calibration functionality

- Large autoranging LED display

- Dedicated to oxygen analysis

- Gas: Oxygen

- Application: Industrial gas, medical gas analysis

- Measurement range: Autoranging from 0.01% to 100% oxygen

- Technology: Paramagnetic

- Response time: T90 < 6 seconds (90% of reading)

Applications

- Gas analysis and testing

Industries

- Industrial

- Medical devices

The MM500 moisture analyzer is designed for application-specific customization, delivering absolute moisture measurement in gases with high precision across a wide range—from 0.01 ppm to 1000 ppm (–110 °C to –20 °C dew point). Measurement units can be selected in ppmv or dew point (°C or °F).

Key Features

- Auto-ranging from 0.01 to 1000 ppm (–110 °C to –20 °C dew point)

- RS232/485 output

- Selectable units: ppmv, °C, °F dew point

- No calibration required

- Remote sensor available

- Fault alarm function

- Measurement range: Auto-ranging from 0.01 ppm to 1000 ppm and equivalent dew point

- Accuracy: ±5% of reading or 0.4 ppm(v) (–110 °C to –20 °C dew point)

- Response time: 90% of reading within 60 seconds

- Compatible gases: N₂, H₂, O₂, Helium, Argon, CO₂, Air, N₂O

- 19-inch rack mounting option: Can be combined with any oxygen analyzer to create a dual gas system

- Gas analysis and testing

- Industrial gas

- Medical gas analysis

- Welding

The EC92DIS is a portable oxygen analyzer approved for use in hazardous environments (II 1G Ex ia IIc Ga T4 – Zone 0 ATEX). It measures oxygen concentrations from as low as 1 ppm to high-percentage levels and is compatible with most industrial gases and atmospheres. The maintenance-free fuel cell and easy calibration using ambient air or standard gases make it highly convenient for field use.

Key Features

- Unique fast purge system

- Simple and quick calibration

- Maintenance-free measuring cell

- Intrinsically safe certification for hazardous areas

- Selectable oxygen ranges in % and ppm

- Powered by 2 × PP3 batteries

- Gas: Moisture

- Technology: Phosphorus Pentoxide (P₂O₅)

- Measurement range: Autoranging from 0.01 ppm to 1000 ppm (with dew point equivalent)

- Accuracy: ±5% of reading or 0.4 ppm(v) (–110 °C to –20 °C dew point)

- Response time: 90% of reading within 60 seconds

- Acceptable gases: N₂, H₂, O₂, Helium, Argon, CO₂, Air, N₂O

- 19-inch rack mounting option: Can be combined with any Systech Illinois oxygen analyzer to form a dual gas system

Applications

- Gas analysis and testing

Industries

- Industrial

- Medical devices

The EC91 is an intrinsically safe online oxygen analyzer designed for ppm and percent-level measurements in hazardous area gas streams. It detects oxygen concentrations from 1 ppm to high percent levels and is compatible with a wide range of industrial gases and atmospheres. The maintenance-free fuel cell offers long-term operation, and calibration is simple using ambient air or certified calibration gases.

Key Features

- Maintenance-free sampling cell with 5-year lifespan

- Certified safety for Zone 0 hazardous areas

- Easy air calibration

- 3-year warranty on electronics

- 36-month overall warranty covering workmanship and component reliability

- Gas: Oxygen

- Measurement range: ppm and % (6 selectable ranges)

- Technology: Electrochemical

- Resolution: 0.05% of scale

- Response time: 90% of reading within 20 seconds

- Ingress protection: IP66, NEMA 4X

- ATEX approval: Zone 0

- Certifications: ATEX Ex II 1G EX ia IIC T4 Ga

- Gas Analysis and Testing

The EC9031 is one of the most advanced and feature-rich oxygen monitors available. It includes adjustable alarm contacts for early warning of oxygen level changes, continuous data transmission to control systems or PLCs, and complete event logging. The unit uses a diffusion-type electrochemical sensor that requires no sample pumping and supports remote mounting for added flexibility.

Key Features

- 4.7" touchscreen with data logging, graphing, and event tracking

- Two adjustable oxygen alarm levels with audible and visual alerts

- 5-year sensor life

- Simple installation

- 3-year warranty

- High measurement accuracy

- IP65 wall-mount enclosure with optional bracket

- Pressure-compensated measurements

- Continuous data logging of oxygen, temperature, and pressure

- Date- and time-stamped measurements

- Sensor life warning alert

- All functions controlled via touchscreen, including alarm mute option

- Large, clear display of oxygen concentration and system status

- Gas detected: Oxygen

- Measurement range: 0–30%

- Technology: Electrochemical

- Resolution: 0.01%

- Accuracy: ±0.001%

- Response time: 90% of reading within 20 seconds

- Ingress protection: IP65

- Operating temperature: 0 °C to 40 °C

Applications

- Gas analysis and testing

- Oxygen deficiency testing

Industries

- Beverage

- Food

- Industrial

- Medical devices

Invest in a powerful ZR800 Series Oxygen Analyzer and gain the ability to measure oxygen levels across most industrial gas streams—from as low as 0.1 ppm up to 100% volume.

Key Features

- Non-depleting, maintenance-free oxygen sensors

- Calibration via ambient air or traceable gas

- Microprocessor-controlled functions

- Large, autoranging LED display

- Extremely fast oxygen response time

- Vibration- and position-insensitive performance

- Robust design with three mounting options

- 24VDC version available

- Panel or bench-top mounting

- NEMA 4X / IP66 waterproof and weatherproof enclosure

- Operator interface with diagnostic tools and read-only mode

- Comprehensive diagnostics and fault alarms

Sampling & Control Options

- Bypass flowmeter

- Pressure regulator

- Sample pump

- Flow alarm

- Auto calibration

- Cartridge filter kit

Communication & Output

- RS232 / RS485 communication

- Analog outputs

- High/low alarms

- Flow and fault alarms

Unsuitable Gases

- Ammonia

- Carbon monoxide

- Combustible gases

- Corrosive gases

- Halogenated hydrocarbons

- Halogens

- Hydrocarbons

- Hydrogen

- Hydrogen sulfide

- Sulfur- or lead-containing compounds

Note: An optional version is available for use with gases containing low ppm levels of hydrocarbons and similar compounds.

- Industrial gas

- Ovens and furnaces

- Welding

The Gaspace Advance oxygen (O₂) and carbon dioxide (CO₂) headspace gas analyzer is ideal for food and pharmaceutical applications. It offers automatic calibration, diagnostics, and control for accurate, repeatable results—critical for HACCP compliance. The intuitive touchscreen interface with large buttons makes testing simple and error-free, requiring no special training and helping maximize production efficiency.

Key Features

- Easy-to-use touchscreen interface

- Five selectable test methods

- Quick setup with intuitive menu navigation

- Auto calibration and self-diagnosis

- Customizable pass/fail test parameters

- Built-in printer

- PC software integration

- Waterproof protective case

- Can piercing station with optional 45° adaptor

- Syringe injection port compatibility

- Microprocessor-controlled touchscreen system

- Can calculate nitrogen gas concentration based on O₂ and CO₂ levels

The Gaspace Advance Micro is a fast and accurate MAP (Modified Atmosphere Packaging) analyzer designed for measuring carbon dioxide (CO₂) and oxygen (O₂) in headspace gas. It is ideal for quality control testing in gas-flushed food and pharmaceutical products.

Applications

- Gas analysis and testing

- Oxygen headspace testing

TME

TM Electronics has been designing and manufacturing precision measuring instruments for over 60 years. With a legacy of innovation, we deliver solutions that enhance both quality and productivity across industries.

Originally focused on metal fabrication, we specialized in that field for two decades. In the early 1980s, we expanded into medical device manufacturing, which led to a broader portfolio of advanced measuring solutions. Since then, our engineering team has developed technologies that serve the automotive, electronics, pharmaceutical, and food production sectors.

Today, TM Electronics is a leader in automated, high-performance testing equipment, including leak testers, flow testers, and package integrity testers.

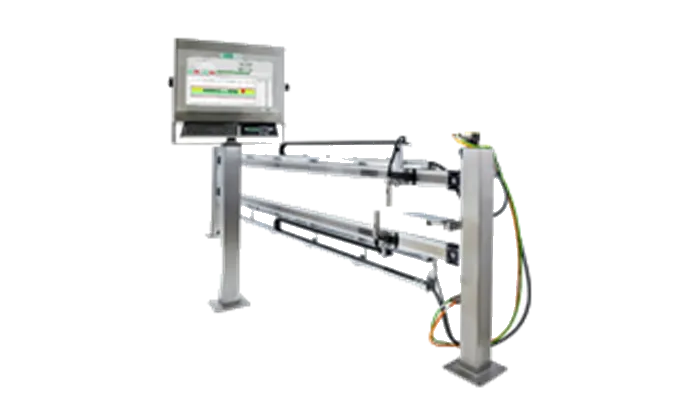

TME’s Integra Flex instruments provide an affordable and flexible solution for leak testing across a variety of environments. The rack-mount model is ideal for integration into OEM systems with data and connectivity support, while the benchtop version suits smaller production lines and R&D labs.

Key Features

- Easy LAN connectivity for streamlined communication

- Rack-mountable design for OEM system integration

- Standard XML data output for seamless data handling

- Compact footprint suitable for space-limited environments

- Remote control capabilities for enhanced factory automation

- Built-in PLC controls and I/O for customized user operations

- Simple integration with Quality Control and IOT systems

| Model | Pressure Range | Accuracy |

|---|---|---|

| Integra Flex 01 | 0 to 100 psig | ± 0.5 psi |

| Integra Flex 02 | -14.7 to +15 psig | ± 0.15 psi |

| Integra Flex 03 | ATM to -14.7 psi vacuum | ± 0.1 psi |

Key Features

- Resolution: 0.0001 psi

- Mains Power: 12 VDC (desktop), 24 VDC (industrial)

- Test Port Fitting: 1/8” FNPT

- Communication Interfaces: Ethernet TCP/IP, RS232, 8-channel I/O

- Optional 8” touchscreen HMI accessory

- Manual pressure regulator

- Applications: Leak Testing

- Industries: Beverage, Flexible Packaging, Food

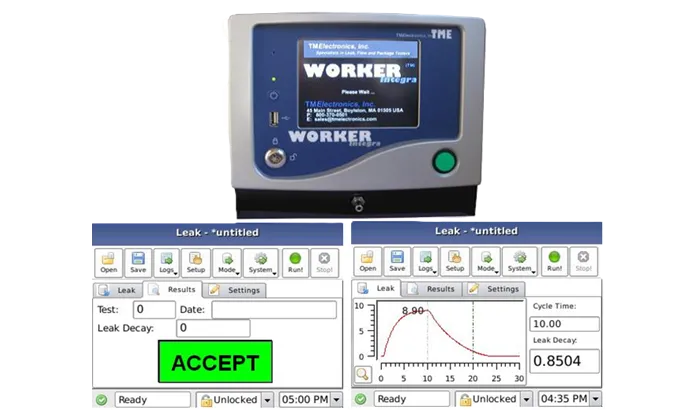

The smart TME WORKER Integra is an advanced instrument designed to simplify and streamline all aspects of leak testing. From programming and test execution to data review and reporting, this intelligent system improves the overall efficiency and usability of the testing process.

Key Features

- High-resolution measurement capability (0.0001 psi)

- Minimized internal volume ensures excellent sensitivity, repeatability, and reliability

- Icon-based touchscreen color display for intuitive control of test parameters and on-screen statistical result analysis

- USB connectivity for direct connection to a PC

- Multiple USB ports support peripherals including keyboard, mouse, printer, and barcode reader

- LAN capability for remote instrument control, data transfer, and automated operation

- Optional electronic pressure regulator available for enhanced control

- Compact footprint: 10" W × 10" D × 9" H

- Security: Key lock access for test control integrity

- Display: 5.7” QVGA color touchscreen interface

- Pressure control: Manual or optional electronic regulator

- Measurement units: psig, inH₂O, mBar, kPa, inHg, ccm, LPM, cfm

- Supported test modes: Leak, Flow, and Occlusion

- Memory: 128 MB internal memory, expandable to 512 MB

- Network connectivity: Built-in LAN access and web-browser interface

- Pressure range: -13.5 to 150 psig

- Pressure resolution: 0.0001 psig across full range

- Pressure accuracy: ± 0.5% of full scale

- Repeatability: Less than 1% (6 sigma/FSD)

- Flow measurement range: up to 10,000 SCCM

- Flow accuracy: ± 2% of full scale

Applications:

- Creep-to-Fail Testing

- Integrity Testing

- Leak Testing

Industries:

- Aerospace

- Automotive

- Defense

- Electronics

- Flexible Packaging

- Food

- Industrial

- Medical Devices

- ASTM D4991 | ASTM D5094 | ASTM F2095 | ASTM F2096

- F-1140 | F-2054

- FDA CFR 21 第 11 部分

- IEC 60529(IP67 等效測試)

- ISO 11607

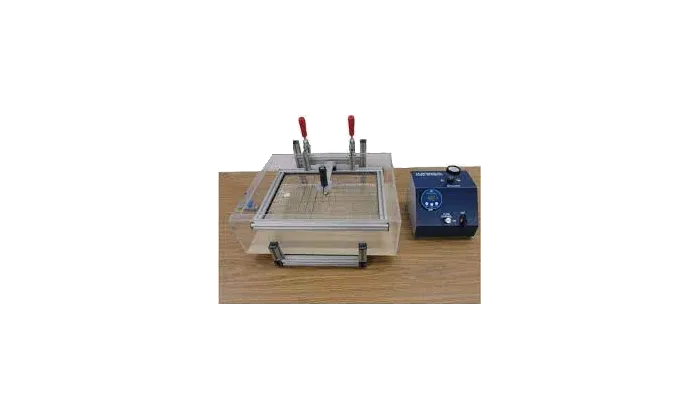

The TME Pressure Bubble Tester delivers low pressure and precise flow to test pouches in accordance with ASTM International F-2096, the standard method for detecting gross leaks in packaging using internal pressurization bubble testing.

Key Features:

- Complies with ASTM F-2096 standards

- Quick and easy setup

- Open screen retainer offers full visibility from all sides

- Retainer locks securely to hold the pouch underwater during testing

- Digital pressure display with backlit screen and selectable measurement units

- Low-pressure control at 2" H2O

- NIST-traceable gauge calibration

- Control Box: Low Pressure Regulator

- Bubble Testing Standard: ASTM F2096

- Adjustable Pressure Levels: 0.1 to 5 PSIG

Applications:

- Creep to Fail Testing

- Integrity Testing

- Leak Testing

Industries:

- Aerospace

- Automotive

- Defense

- Electronics

- Flexible Packaging

- Food

- Industrial

- Medical Devices

- Pharmaceutical

- ASTM D5094

- ASTM F2096

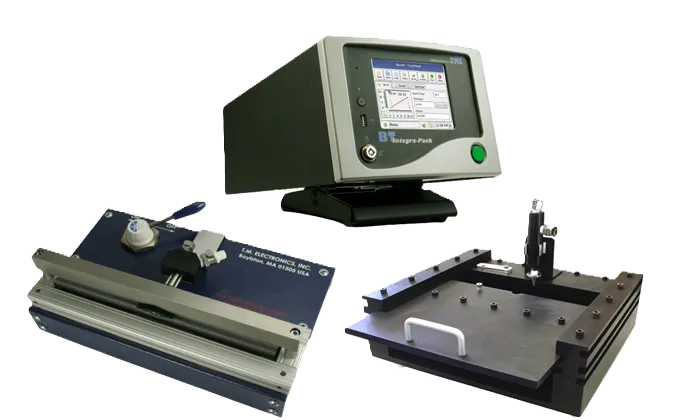

Smart BT Integra-Pack – Package Tester for Burst, Creep, Creep-to-Failure, and Leak Integrity Testing

Key Features:

- Compact bench-top instrument with high resolution (0.001 psig)

- Small footprint with intuitive operation for ease of use

- Electronic pressure and flow control ensure precise, repeatable test conditions

- Automatic high-flow output suitable for testing large porous packages

- Supports a variety of package types including flexible, rigid, porous, non-porous, open, and sealed packages

- Compliant with industry standards for Burst, Creep, Creep-to-Failure, and Leak Integrity testing

- Automatic Burst Test Mode delivers fast results without lengthy setup

- Pre-fill sensing automatically adjusts for package size

- Manual Burst Test Mode offers detailed control over test parameters

- Customizable settings for Ramp Rate, package type, acceptance limits, and pressure drop sensitivity

- Smart user interface with USB compatibility for keyboard, mouse, and barcode reader

- Low Power Stand-by Mode supports energy-efficient operation

- Real-time graphical test plots for burst, creep, and leak tests

- Flash drive export for convenient data transfer to PC

- Higher pressure resolution: 0.01 psi for burst testing, 0.001 psi for leak testing

- Automatic regulator for fast and precise pressure setting

- High flow capacity up to 15 CFM for large volume applications

- Low pressure sensitivity down to 5 inches of H2O

- High-resolution color LCD display with touchscreen interface

- Supports both standard and metric units

Applications:

- Burst Testing

- Creep to Fail Testing

- Leak Testing

- Strength Testing

Industries:

- Flexible Packaging

- Food

- Medical Devices

- Pharmaceutical

- ASTM F2095 | ASTM F2096

- F-1140 | F-2054

- FDA CFR 21 part 11

- ISO 11607