Teledyne Leeman Labs is a leading analytical instrument company trusted by corporations, government agencies, municipalities, and academic institutions across the United States and in over 50 countries worldwide. Founded in 1981, the company is headquartered in Hudson, New Hampshire.

Teledyne Leeman Labs is committed to ongoing investment in research and development to ensure a steady stream of technological advancements for our customers well into the future.

Prodigy ICP

The inductively coupled plasma optical emission spectrometer (ICP-OES) features a high-resolution, long focal length Echelle optical system combined with a large-format, programmable array detector (L-PAD) with over a million pixels. It enables full-spectrum analysis across a wide wavelength range of 134–1100 nm in a single exposure. This design ensures excellent spectral resolution, high stability, and efficient data acquisition—making it easier to extract meaningful information from complex samples.

The patented L-PAD detector provides broad wavelength coverage and high-resolution performance. Unlike standard CCD or CID detectors, L-PAD eliminates overflow issues and offers superior accuracy by simultaneously capturing both peak and background intensities across all wavelengths.

Key Features

- Simultaneous, full-spectrum detection in a single exposure

- Patented L-PAD detector—4× larger active area than typical CID, without CCD overflow artifacts

- Over 1 million pixels for fingerprint-style spectral profiling

- Wavelength range: 134 to 1100 nm

- Capable of halogen analysis (Cl, Br, I)

- Compatible with laser ablation systems for direct solid sample analysis

- Spectral resolution: ≤ 0.005 nm at 200 nm

- Selectable dual-view geometry (horizontal or vertical) via software

Mercury Analysis - Hydra IIAA Mercury Analyzer

The Hydra IIAA Cold Vapor Atomic Absorption (CVAA) Mercury Analyzer combines outstanding analytical performance with high-throughput productivity. Designed to meet strict regulatory standards, it offers detection limits as low as ≤5.0 ng/L, robust long-term stability, and unique over-range protection. Its high-capacity autosampler and contamination control features allow for efficient, unattended operation—ideal for demanding laboratory environments.

Performance

- Low detection limits: ≤5.0 ng/L

- Wide dynamic range: from ng/L to mg/L—fewer dilutions required

- 3rd-generation gas/liquid separator handles foamy or difficult samples

- Excellent long-term stability ensures QC compliance

- Direct analysis option eliminates the need for sample preparation

Productivity

- High-capacity autosampler: standard 180 samples, expandable to 270

- Large CCV/CCB reservoirs for extended unattended runs

- Smart Rinse function reduces sample cycle time

Advanced Contamination Control

- Over-range protection to safeguard results and equipment

- Flow-through rinse system

- Interchangeable sample introduction system for flexibility

Unparalleled Support

- Built-in maintenance scheduling

- On-screen audio/visual help guidance

- Overnight service availability

QuickTrace® M-7600 Mercury Analyzer

The QuickTrace® M-7600 CVAA Mercury Analyzer is engineered for ultra-trace mercury detection, achieving detection limits below 0.5 ng/L to meet the stringent requirements of EPA Method 245.7. Designed for both routine and research environments, it is ideal for environmental labs, industrial facilities, and academic institutions handling virtually any aqueous sample.

Performance

- Ultra-trace detection: Typical instrument detection limits < 0.3 ng/L

- Low sample volume requirement: < 25 mL per analysis

- Fast analysis: < 4 minutes per sample

- Excellent short- and long-term stability

Key Features

- EPA method compatibility: 245.1, 245.5, 245.7, SW 846-7470, and SW 846-7471

- Patented non-foaming gas-liquid separator (GLS)

- Overflow prevention system in GLS

- Detector saturation prevention with Smart Rinse for high-concentration samples

- Patented double beam optics for superior baseline stability

- Thermally stabilized, ozone-free mercury excitation lamp with feedback control

- Smart rack technology and TCP/IP communication compatibility

- Maintenance-free Nafion® dryer

- Filtered CCD detection system

- Internal universal switching power supply

- Manual or autosampler operation (ASX-260, ASX-520 optional)

- Supports unlimited QC sample positions and up to 84 samples in a single unattended run

- Peristaltic pump: 12-roller, 4-channel design

- Sample volume range: 0.5 mL to >20 mL

- High-capacity mode: < 60 seconds per sample

- Powder-coated metal construction for durability

- Intuitive QuickTrace™ software with built-in calibration, QC tools, and EPA-compliant reporting

QuickTrace M-8000 Mercury Analyzer

The patented non-foaming gas-liquid separator with built-in overflow prevention helps the instrument easily achieve its detection limits. Multiple autosampler sizes are compatible, and intelligent design features—such as contamination prevention from high-concentration samples and smart rinsing functions—make mercury analysis more efficient and user-friendly.

Key Features

- Patented non-foaming gas-liquid separator with overflow protection

- Compatible with various autosampler sizes

- Smart contamination prevention from high-concentration samples

- Intelligent rinse system simplifies mercury analysis workflow

- Three interchangeable analysis modes compliant with CVAFS regulatory methods:

- CVAFS-SGTA (Single Gold Trap Amalgamation)

- CVAFS-DGTA (Double Gold Trap Amalgamation)

Hydra IIC Mercury Analyzer

The Hydra IIC is a fully automated, turnkey mercury analyzer designed for direct analysis of solid and semi-solid samples—no acid digestion or sample preparation required. It utilizes thermal decomposition (combustion), mercury concentration via gold amalgamation, and cold vapor atomic absorption detection.

This system eliminates the need for chemical reagents and waste disposal, significantly simplifying lab operations while improving efficiency and environmental safety.

Key Features

- No sample preparation required; no waste generated

- Wide dynamic range with optional extended range capability

- Excellent sensitivity—no sample dilution needed

- Easy calibration; matrix-independent performance

- Electronic transfer of sample weight

- Simple “plug and play” design for easy preventative maintenance

- Accommodates “on-the-fly” sample introduction

ICP-OES

The Prodigy7 is one of the most advanced solid-state ICP-OES systems ever developed, offering a complete solution for elemental analysis. It features wide dynamic range, low detection limits, exceptional wavelength resolution, long-term stability, and true simultaneous multi-element detection.

Covering wavelengths from 165 nm to 1100 nm, the Prodigy7 includes the cesium 894 nm line—60× more sensitive than previous ICP-OES lines. This system combines cutting-edge technology with intuitive operation, delivering a powerful and compact platform refined through years of innovation.

Key Features

- Twist-n-Lock auto-aligning sample introduction system

- High-energy, high-performance optical system

- Full wavelength coverage: 165–1100 nm

- Low stray light optics with 0.007 nm resolution @ 200 nm

- Large-format CMOS array detector for true simultaneous measurement

- User-friendly Salsa Software

- Full Spectral Access (FSA): captures the entire spectrum in a single reading

- Compact benchtop footprint

- Fast startup and reduced gas consumption

- Available in axial, radial, and dual-view configurations

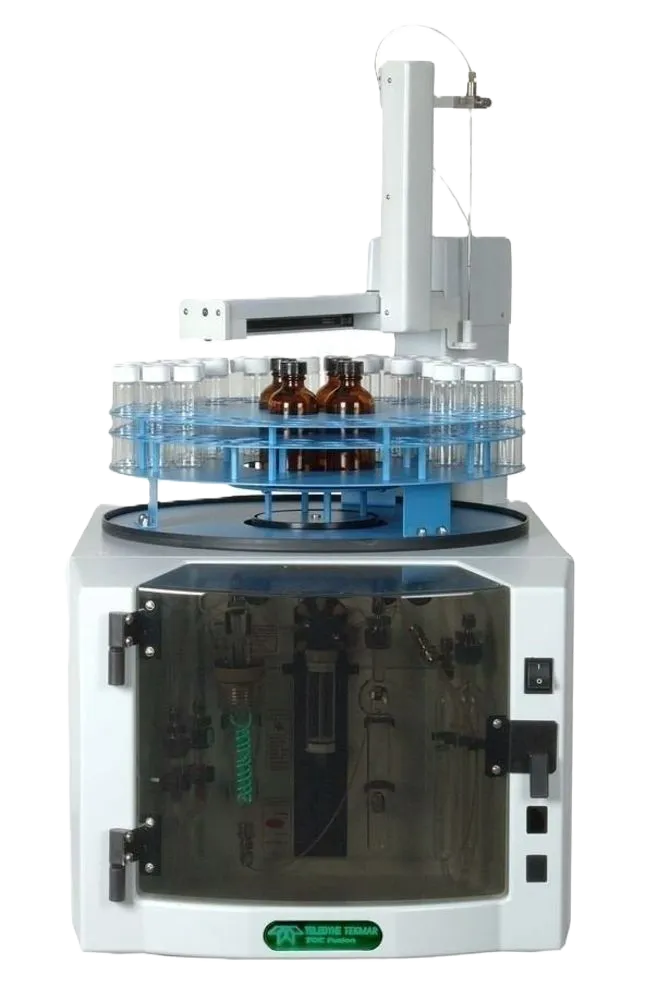

TOC Analyzer Fusion UV/Persulfate TOC Analyzer

The Fusion TOC Analyzer utilizes powerful UV persulfate oxidation for effective carbon release from even the most complex matrices. With patented Static Pressure Concentration (SPC) technology, it achieves exceptional low-end sensitivity using a Non-Dispersive Infrared (NDIR) detector. Built with the latest innovations, the Fusion is ideal for high-throughput and regulatory-compliant environments.

Key Features

- Walk-away automation and intuitive TekLink™ software control

- Unattended auto-calibration monitoring

- Automatic dilution from stock standards or sample matrix

- Intellidilution: Automatically adjusts samples back into calibration range

- Automated diagnostics, including leak check

- 21 CFR Part 11 compliance: electronic records, signatures, audit trails, and user management

- Customizable and exportable reports with metadata and version control

- Turnkey method development and scheduling tools

- Mass Flow Controller (MFC) for reduced carrier gas consumption and precision control

Torch Combustion TOC Analyzer

The Torch Analyzer contains a built-in autosampler with three vial rack choices and PC-driven control. It features automated calibration and Intellidilution, which automatically dilutes over-range samples to fall within the working calibration range. Maintenance is simplified by design, allowing easy access to all areas of the unit.

Key Features

- Built-in benchmark diagnostic check – including leak check

- Programmable furnace temperatures for various analytical methods

- Static Pressure Concentration Technology (patent pending)

- Intellidilution automatically detects and dilutes over-range samples

- Multiple pre-set application ranges for diverse analytical needs

- Auto-calibration eliminates manual standard preparation

- Detection Limits:

- Carbon: 50 ppb to 30,000 ppm

- Nitrogen: 50 ppb to 2,000 ppm

- Simultaneous Carbon and Nitrogen analysis

- Easy access for combustion tube maintenance

- Enhanced catalyst for improved performance

- Built-in autosampler for increased efficiency

- Higher throughput enabled by ASM Sparge

- Auto-blanking functionality

- Mass Flow Controller included

- Optional vial mixing capabilities

- Optional TN Module available

Lotix Combustion TOC Analyzer

Simple, high performance, and durable — the design philosophy behind the LOTIX TOC Analyzer

The LOTIX combustion-based Total Organic Carbon (TOC) analyzer is purpose-built for analyzing carbon content in water samples. It can accurately measure TOC concentrations down to ppb levels. Using high-temperature combustion, organic carbon in the sample is oxidized to CO₂, and a non-dispersive infrared (NDIR) detector precisely measures carbon concentration. LOTIX is suitable for analyzing wastewater, drinking and tap water, surface water, seawater, and other hard-to-oxidize matrices. Its affordable pricing makes it a perfect fit for a wide range of budgets.

Key Features

- Innovative design without syringe injector or 7-port valve

- Single calibration curve for analysis range 0–20,000 ppm

- Capable of analyzing seawater (3.5% salinity), high concentration wastewater, and petrochemical samples

- New combustion tube and catalyst for longer lifespan and higher sample throughput

- User-friendly software allows calibration setup in under 1 minute

- Simplified design for easy maintenance and component access

- Front-mounted combustion tube for easy removal and replacement

- Real-time data monitoring and ability to retrieve completed results during analysis

- Data export options in CSV or PDF format; import CSV for data analysis

- Triplicate sample analysis takes only 13–15 minutes

- High-pressure DI water rinses tubing and sampler between samples to reduce cross-contamination

Optional module: LSS Boat for solid sample analysis

To meet the diverse needs of TOC users, Tekmar developed the LSS solid sample analysis module compatible with the LOTIX system. Using high-temperature combustion, it accurately measures organic carbon in various matrices including soil, sludge, sediments, particle-laden liquids, and other difficult samples. The modular design and affordable pricing provide a complete solution for both liquid and solid sample analysis.

- Automated sample introduction to the combustion furnace via software control

- Low operating cost

- Wide analysis range — up to 1g sample capacity

- Quick switching between liquid and solid sample modes

- Up to 20 mg of organic carbon detectable from a 1g sample, reducing error from small-volume sampling