TM Electronics has been designing and manufacturing precision measuring instruments for over 60 years. With a legacy of innovation, we deliver solutions that enhance both quality and productivity across industries.

Originally focused on metal fabrication, we specialized in that field for two decades. In the early 1980s, we expanded into medical device manufacturing, which led to a broader portfolio of advanced measuring solutions. Since then, our engineering team has developed technologies that serve the automotive, electronics, pharmaceutical, and food production sectors.

Today, TM Electronics is a leader in automated, high-performance testing equipment, including leak testers, flow testers, and package integrity testers.

Integra Flex

TME’s Integra Flex instruments provide an affordable and flexible solution for leak testing across a variety of environments. The rack-mount model is ideal for integration into OEM systems with data and connectivity support, while the benchtop version suits smaller production lines and R&D labs.

Key Features

- Easy LAN connectivity for streamlined communication

- Rack-mountable design for OEM system integration

- Standard XML data output for seamless data handling

- Compact footprint suitable for space-limited environments

- Remote control capabilities for enhanced factory automation

- Built-in PLC controls and I/O for customized user operations

- Simple integration with Quality Control and IOT systems

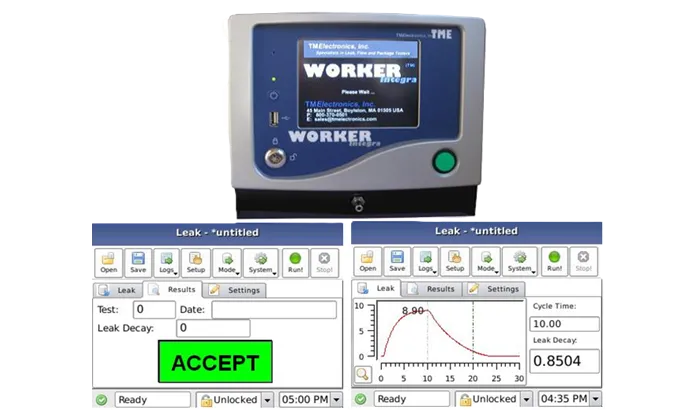

LT-V/L WORKER Integra

The smart TME WORKER Integra is an advanced instrument designed to simplify and streamline all aspects of leak testing. From programming and test execution to data review and reporting, this intelligent system improves the overall efficiency and usability of the testing process.

Key Features

- High-resolution measurement capability (0.0001 psi)

- Minimized internal volume ensures excellent sensitivity, repeatability, and reliability

- Icon-based touchscreen color display for intuitive control of test parameters and on-screen statistical result analysis

- USB connectivity for direct connection to a PC

- Multiple USB ports support peripherals including keyboard, mouse, printer, and barcode reader

- LAN capability for remote instrument control, data transfer, and automated operation

- Optional electronic pressure regulator available for enhanced control

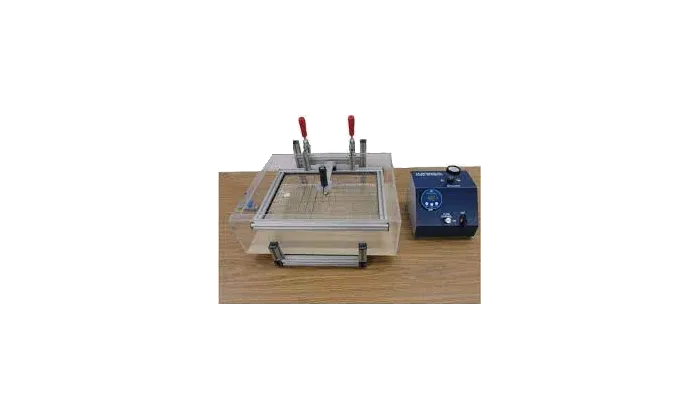

PA-2096 TME Pressure Bubble Tester

The TME Pressure Bubble Tester delivers low pressure and precise flow to test pouches in accordance with ASTM International F-2096, the standard method for detecting gross leaks in packaging using internal pressurization bubble testing.

Key Features:

- Complies with ASTM F-2096 standards

- Quick and easy setup

- Open screen retainer offers full visibility from all sides

- Retainer locks securely to hold the pouch underwater during testing

- Digital pressure display with backlit screen and selectable measurement units

- Low-pressure control at 2" H2O

- NIST-traceable gauge calibration

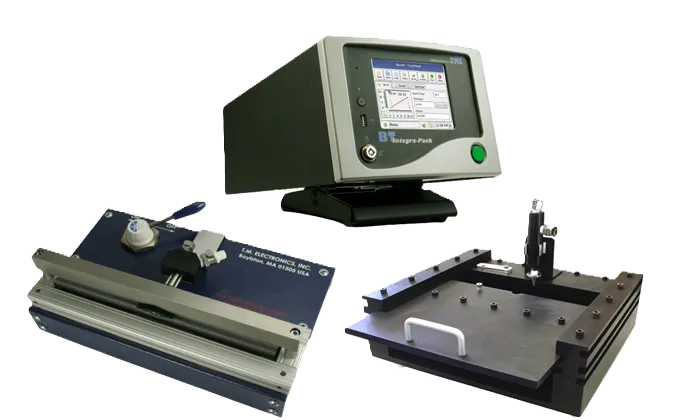

BT-IP BT Integra Pack: Smart Package Tester

Smart BT Integra-Pack – Package Tester for Burst, Creep, Creep-to-Failure, and Leak Integrity Testing

Key Features:

- Compact bench-top instrument with high resolution (0.001 psig)

- Small footprint with intuitive operation for ease of use

- Electronic pressure and flow control ensure precise, repeatable test conditions

- Automatic high-flow output suitable for testing large porous packages

- Supports a variety of package types including flexible, rigid, porous, non-porous, open, and sealed packages

- Compliant with industry standards for Burst, Creep, Creep-to-Failure, and Leak Integrity testing

- Automatic Burst Test Mode delivers fast results without lengthy setup

- Pre-fill sensing automatically adjusts for package size

- Manual Burst Test Mode offers detailed control over test parameters

- Customizable settings for Ramp Rate, package type, acceptance limits, and pressure drop sensitivity

- Smart user interface with USB compatibility for keyboard, mouse, and barcode reader

- Low Power Stand-by Mode supports energy-efficient operation

- Real-time graphical test plots for burst, creep, and leak tests

- Flash drive export for convenient data transfer to PC