Napra has successfully developed and manufactured the world's first homogeneous fine alloy particles featuring a nano-composite structure.

These patented fine alloy particles deliver breakthrough performance, offering innovative solutions for the manufacturing of semiconductor devices and next-generation precision electronic components.

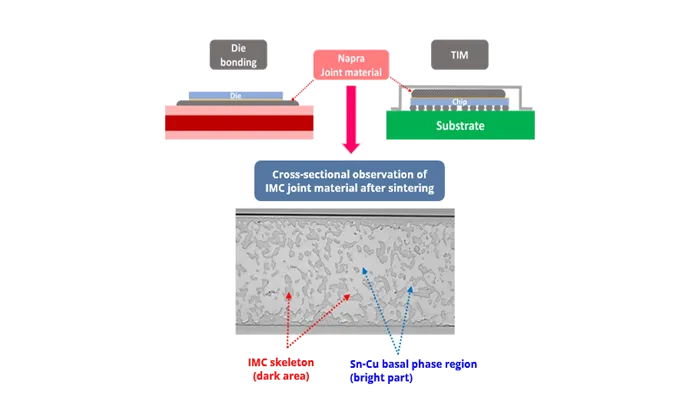

IMC joint material

Napra’s advanced joint materials, available in IMC sheet and paste forms, are based on a Cu-Sn-Ni metal alloy system. These materials are designed for die and substrate attachment and can also serve as thermal interface materials (TIM) or die bonding solutions.

Key Features

- Cost-effective alternative to Ag and Cu sintering technologies

- Enables high-temperature operation with low-temperature processing, ideal for high-power devices

- Excellent reliability performance, including TCT, HTSL, and die shear strength

- Suitable for large-area joints with minimal void formation

- Helps prevent voids, delamination, and cracking during operation