Core Insight has been deeply engaged in the EOS/ESD field for many years, specializing in the sales of ESD eliminators and anti-static devices, as well as providing on-site consulting services for EOS/ESD issues in semiconductor, flat panel display, and electronics assembly processes. The company possesses in-depth expertise in EOS/ESD management.

Established on March 26, 2003, and headquartered in Gyeonggi-do, Korea, Core Insight has grown into a trusted partner by not only supplying products but also solving complex challenges for customers. Their goal is to become a global business partner offering innovative solutions in the EOS/ESD field.

Core Insight is also actively involved in non-profit initiatives, supporting organizations such as the Korean Static Electricity Association and the EOS/ESD Association. Through academic research and regular events, they aim to advance global understanding of EOS/ESD in the electronics industry.

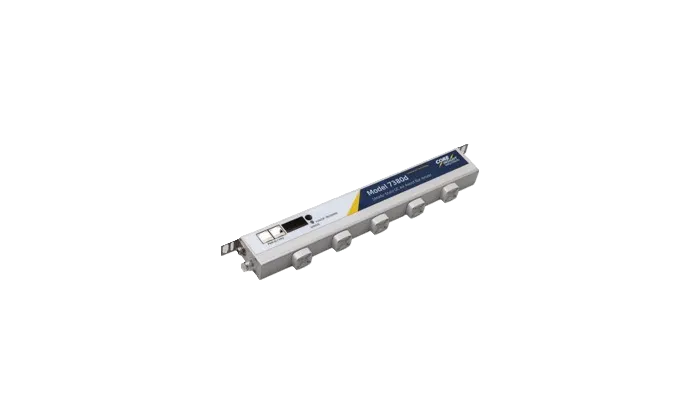

Model 7380d AirStat® Steady-State DC Bar Ionizer

The Model 7380d AirStat® Steady-State DC Bar Ionizer is specifically engineered for ultra-sensitive and high-speed device applications. Featuring the patented QuadPoint® nozzle design, this system ensures a truly low offset voltage unmatched by other technologies across the industry. Unlike AC switching systems, the steady-state DC ionization method does not produce induction fields, reducing the risk of ESD damage in advanced packaging processes, including 2.5D and 3D IC manufacturing.

Compact and versatile, the 7380d AirStat® Ionizer is ideal for space-constrained environments such as inside Automated Handling Equipment (AHE) and other critical areas. Its precise voltage control and exceptionally low peak offset make it perfectly suited for handling sensitive devices. It is also the only air-assisted bar ionizer compliant with the ANSI/ESD S20.20 program, meeting ion balance specifications of less than ±5 volts, with capabilities extending to single-digit voltage levels.

Key Features

- Steady-State DC ionization technology

- Patented QuadPoint® nozzle design

- Ion balance less than ±5 V

- Integrated ion balance alarms

- No high-voltage switching

- No induction field generation

Model 3810E CoreStat® Self-Balanced Air Ionizing Blower

Tribocharging is a common source of electrostatic discharge (ESD), and induced fields from insulators must be strictly controlled within ESD Protected Areas (EPAs). Insulating materials essential to certain processes are used widely and must be neutralized using ionization systems to prevent charge accumulation.

The Model 3810E ionizing blower, featuring CoreStat® self-balanced technology, is engineered to meet Class 0 ESD requirements. It is ideal for semiconductor back-end operations, PCB assembly, and general electronics manufacturing. The blower requires no routine calibration, and its self-balancing design ensures consistently low offset voltage.

Integrated with Facility Monitoring System (FMS) support, the 3810E offers real-time status reporting. The unit features both visual (LED) and audible (buzzer) alarms for HV power failure and out-of-balance conditions. A built-in auto-cleaning brush significantly reduces maintenance time and costs.

Key Features

- Meets Class 0 ESD standards

- CoreStat® self-balanced technology for consistent performance

- Automatic safety stop function

- Visual and audible alarm indicators

- Integrated FMS interface for real-time monitoring

- Built-in auto-cleaning mechanism