辛耘公司取得ClassOne Technology在台灣、中國以及東南亞地區之代理權

ClassOne Signs Scientech as Rep for China, Taiwan and SE Asia

ClassOne Technology | March 8, 2017

Kalispell, Montana – ClassOne Technology (www.classone.com), manufacturer of wet processing equipment for 200mm and smaller wafers, announced that Scientech Corporation of Taipei, Taiwan, will become the company’s new representative for China, Taiwan and Southeast Asia, starting immediately.

Asia is an extremely active and important region for us," said Byron Exarcos, President of the ClassOne Group. "We wanted a respected and thoroughly experienced sales and support operation there, and Scientech filled the bill perfectly. They have all the necessary infrastructure and well-established field service teams, having served the industry for over three and a half decades — including many years representing Semitool. We’re proud and delighted to now have them on the ClassOne team.

We're very impressed by the rapid success ClassOne has been achieving, bringing high-performance wet processing solutions to the emerging markets — with more than 100 tools already installed across the U.S. and Europe," said M.T. Hsu, President of Scientech Corporation. “It's great to represent products that are in high demand, and we're looking forward to helping expand ClassOne's presence in Asia.

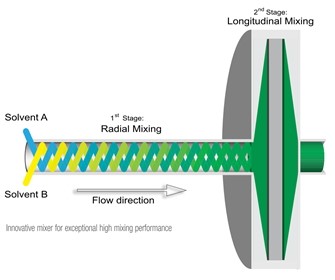

Scientech Corporation (www.scientech.com) was established in 1979 and has headquarters in Taipei, Taiwan, with five additional offices across Taiwan and Shanghai. Scientech will provide full sales, installation, service, parts, process development assistance and technical support for all ClassOne Technology equipment — including the Solstice® family of electroplating systems and the Trident® families of Spin Rinse Dryers and Spray Solvent Tools.

ClassOne stated that the company's mission is to provide advanced wet processing performance at an affordable price for users of 200mm and smaller substrates. Many of these users are in budget-limited emerging markets producing a range of devices such as MEMS, LEDs, RF, power and sensors. ClassOne's pricing is often less than half that of similarly configured 300mm systems outfitted for 200mm from the large manufacturers — which is why ClassOne tools have been described as delivering "Advanced wet processing for the rest of us."