ELTRA

ELTRA is one of the world's leading manufacturers of elemental analyzers for rapid and accurate analysis of solid materials. ELTRA elemental analyzers provide tailor-made solutions for a wide range of samples and concentrations. Thousands of satisfied customers worldwide are proof of the quality and reliability of ELTRA analyzers.

- ELEMENTRAC CN-r

- Carbon / Sulfur Analyzer ELEMENTRAC CS‑i

- Carbon / Sulfur Analyzer ELEMENTRAC CS‑r

- CHS Analyzers CHS-580A

- Carbon / Water Analyzer CW‑800M

- Oxygen / Nitrogen / Hydrogen Analyzer ELEMENTRAC ONH‑p 2

- Oxygen / Nitrogen / Hydrogen Analyzer ELEMENTRAC ONH-2000

- Hydrogen Analyzer H-500

- Thermogravimetric Analyzer TGA Thermostep

ELEMENTRAC CN-r

The ELEMENTRAC CN-r is an advanced nitrogen and carbon analyzer designed for high-throughput laboratories,where samples are burned in a pure oxygen atmosphere. All components are completely oxidized using a chromium-free catalyst, ensuring accurate nitrogen and carbon analysis. . It provides fully automated and process-optimized nitrogen and carbon determination using the Dumas method, offering rapid, accurate results with minimal operational costs.The use of non-corrosive chemicals ensures greater work safety compared to Kjeldahl method.Available in two configurations: carbon and nitrogen / protein analyzer, or nitrogen / protein analyzer only.

Main features

● High Throughput: Specially engineered for continuous operation, enabling fast sample analysis and high durability.

● Smart Integrated Design: Equipped with an ergonomic design and built-in PC featuring a tiltable touchscreen, ensuring ease of use.

● Cost-Efficiency: Low operating costs due to intelligent gas-saving functions and optimal resource consumption.

● Wide Sample Range: Suitable for various solid and liquid matrices, ensuring accurate results across different industries.

● Effortless Maintenance: Quick maintenance, with consumables easily replaced in under 20 minutes, minimizing downtime.

Standard Certification

Application

● Foodstuffs

● Animal feed

● Fuels (coal, coke)

● Fertilizers

● Environmental samples

Specification

Measuring range: Nitrogen: 0.03 mg to 300 mg / Carbon: 0.02 mg to 175 mg

Typical weight: up to 1.0 g, nominal 0.5 g

Analysis time: < 3 minutes

Detector: Thermal conductivity detector (N) / NDIR (C)

Power supply: 230 V ±10%, 50/60 Hz

Required gases: Oxygen (99.999% purity) / Helium (99.996% purity) / Compressed air (oil-free, water-free)

Weight: 135kg

Dimensions: 75.7 x 78.5 x 62 cm (W x H x D)

Carbon / Sulfur Analyzer ELEMENTRAC CS‑i

The elemental analyzer ELEMENTRAC CS-i measures the carbon and sulfur concentration in predominantly inorganic samples through combustion in an induction furnace and the subsequent analysis of the gaseous combustion products carbon dioxide and sulfur dioxide.

The high temperature of more than 2000 °C ensures complete decomposition of the sample and thus reliable and accurate elemental analysis over a wide concentration range.

Main features

●Control of induction performance provides precise analysis of low-melting metals

●Heated dust trap allows for improved sulfur detection

●Platinum-based catalyst reactor ensures accurate carbon detection

●Carrier gas flow optimized for dusty samples

●Software-based leakage test

●Optional vacuum system, also available with dust filter class H for potentially harmful samples

●Single and multipoint calibration

●Robust design allows usage in production control and laboratory

●Low maintenance

Standard Certification

The ELEMENTRAC CS-i meets and exceeds the requirements of all common standards for carbon and sulfur measurement, such as ASTM E1019, DIN EN ISO 153

Application

alloys, aluminum, ashes, carbides, cast iron, cement, ceramics, copper, ferroalloys, glass, gypsum, iron, limestone, metals, minerals, ores, refractory metals, sand, silicon, slag, soil, steel, …

Specification

Carbon / Sulfur Analyzer ELEMENTRAC CS‑r

In the elemental analyzer CS-r the sample is burnt in an oxygen atmosphere at temperatures up to 1,550 °C. The furnace temperature can be freely selected in steps of 1 °C. The combustion gasses (CO2, H2O, SO2) coming from the furnace and pass through a dust filter. After the water vapor is chemically absorbed, the dried CO2 and SO2 gas is detected in the additional infrared cells. Depending on the configuration, it is possible to combine up to four (for C, S analyzers) infrared cells with different sensitivities.

For the safe, precise and reliable elemental analysis of carbon (C) and sulfur (S) in predominantly organic matrices such as soils, waste, wood, oil, coal and coke, ELTRA offers the combustion analyzer ELEMENTRAC CS-r with IR detection.

Main features

●Fast, simultaneous measurement of carbon and sulfur

●High sample weight possible

●Optimized (low blank) sample port

●IR path made of solid gold for extended lifetime

Wide measuring range from 20 ppm to 100%

Standard Certification

The CS-r elemental analyzer meets or exceeds the requirements of all common ASTM, DIN, EN or ISO standards for elemental analysis.

Application

biomass, building materials, coal/ coke, fuels, oil, ores, plant materials, plastics, rubber, soil, soot, tobacco, waste, …

Specification

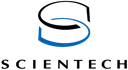

CHS Analyzers CHS-580A

ELTRA‘s CHS-580A is the ideal elemental analyzer for simultaneous determination of carbon, hydrogen and sulfur in organic samples. It features a resistance furnace with vertical ceramic tube and uses ceramic crucibles as sample carriers.

Main features

●Fast & simultaneous elemental analysis of C, H, S, TOC and TIC

●Configurable for single element (C or S) or multi-element (C/S or C/H/S) analysis

●Wide concentration range from 0.005 – 100 %

●High weights possible for elemental analysis of heterogeneous samples

●Optional autoloader with 36 or 130 positions (acid-resistant version available)

●Optional TIC module

Standard Certification

DIN EN 15936

ASTM D 6316; D 7679; D 7662; D 7633

ASTM D 1552; D1619; D4239; D5016

ISO 19579; 15178

Application

The CHS-580 A elemental analyzer is perfectly suited for measuring carbon, hydrogen and sulfur concentrations in matrices such as ashes, building materials, coal, coke, gypsum, limestone, oil, plant materials, rubber, sand, soil, soot, tobacco, waste, …

agriculture, biology, chemistry / plastics, coal / power plant, construction materials, environment / recycling, medicine / pharmaceuticals

Specification

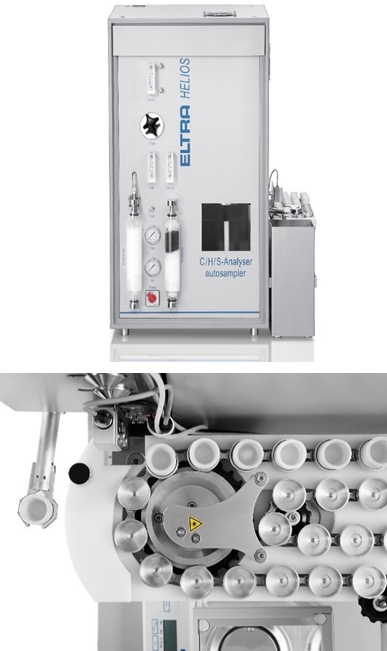

Carbon / Water Analyzer CW‑800M

ELTRA’s CW-800M analyzer is designed for fractional analysis of carbon and water in one single operation. It is based on the proven technology of the CW-800 but has a modified furnace which allows fast adjustment of the temperature in the furnace. Different fractions of carbon and water of the sample are analyzed by applying different furnace temperatures.

The detection system of ELTRA’s CW-800M is very sensitive, reliable and guarantees a long lifetime. It can be customized according to the user’s requirements. Two infrared cells can be combined independently and allow highly precise measurement of the released CO2 and H2O.

Main features

●Simultaneous carbon dioxide and water determination with minimal sample preparation

●Analysis of TOC (Total Organic Carbon) and TIC (Total Inorganic Carbon) without adding acids

●Rapid, precise, accurate and reliable element determination

●Up to 5 programmable steps with different temperatures ("ramps") can be defined

●Wide range of materials can be analyzed

●Resistance furnace temperature can be set up to 1000 °C in steps of 1 °C

●Customized infrared cells provide wide, dynamic measuring range

●Due to gold IR path, increased cell life time for analysis of halogen or acid containing samples

●Powerful software (multilingual, customized display, export of results)

●Single and multipoint calibration

●No halogen trap required

●Electronic gas flow control

●Low maintenance

●Robust design allows usage in production control and laboratory

Standard Certification

Application

ELTRA’s CW-800M analyzer is designed for the precise, simultaneous determination of carbon (released as CO2) and water in lime, gypsum and cement from trace level up to 100 % (depending on sample weight). Other sample materials include ores, soil, minerals, slags and waste.

Field of application : agriculture, biology, chemistry / plastics, construction materials, environment / recycling, geology / mining, others.

Specification

Oxygen / Nitrogen / Hydrogen Analyzer ELEMENTRAC ONH‑p 2

The new ELEMENTRAC ONH-p 2 is a powerful and robust elemental analyzer for measurement of oxygen, nitrogen and hydrogen concentrations in inorganic materials like steel, iron, copper or ceramics. The highly sensitive NDIR and thermal conductivity detectors reliably detect element concentrations from low ppm content to high percentages.

The innovative sample port system with pulsed chamber rinsing and vertical sample drop allow for user-friendly and comfortable analysis of rod-shaped, granular or powdery samples with a weight of up to 2 grams.

Main features

●Low gas consumption and high sensitivity due to closed gas system

●Easy application of pins, powders and granules

●Inexpensive argon as carrier gas possible

●Short analysis time

●Powerful impulse furnace with 8.5 kW

●Optional Autocleaner

●Reliable ONH elemental analysis of inorganic samples like steel, non-ferrous metals, ceramics, slags, ores, etc.

Standard Certification

ASTM E 1019; E 1509; E 1557;

C 1595; E 2575; E 2792

DIN EN 3976

DIN EN ISO 10720; 15351

21068-3

ISO 17053; 22963

DIN 55387

Application

alloys, aluminum, ashes, carbides, cast iron, ceramics, copper, ferroalloys, iron, metals, ores, refractory metals, silicon, steel, …

Specification

Oxygen / Nitrogen / Hydrogen Analyzer ELEMENTRAC ONH-2000

The ONH-2000 is designed for the rapid and accurate determination of oxygen, nitrogen and hydrogen in copper, steel, cast iron, alloys, zirconium, titanium, molybdenum, nickel, ceramics and other inorganic materials. The ONH-2000 can be supplied with two independent infrared cells to provide optimum precision for the analysis of high and low levels of oxygen. Nitrogen and hydrogen are detected with a dual range thermal conductivity cell. The change over from the low to the high ranges is done automatically during the analysis and does not require any pre-setting by the operator.

Main features

●The ONH-2000 features a 16-bit microprocessor and solid state infrared detectors with auto zero and auto range control.

●The water cooled high power electrode impulse furnace uses a graphite crucible to heat the sample up to a temperature of 3000°C.

●On request the ONH-2000 measuring ranges can be optimized in the factory to suit your requirements, without additional charges.

●The sensitivity of the detectors can be designed to provide maximum accuracy in ranges from low ppm up to high percentage concentrations.

Standard Certification

ASTM E-1019, E-1587, E-1409, E-1569, E-1447, E-1937

Application

alloys, steel, copper, cast iron, ceramics, refractory metals

Specification

Hydrogen Analyzer H-500

Determination of hydrogen using the heat extraction method is a special requirement for the characterization of steel, steel alloys, copper and other metals. ELTRA’s H-500 is designed for the rapid and accurate determination of hydrogen in these materials.

The H-500 analyzer uses the heat extraction technique and is equipped with a resistance furnace with quartz tube. The temperature can be set up to 1000 °C in steps of 1 °C. The usual working range of the H-500 is about 900° to 1000° C.

ELTRA’s H-500 can be customized to the requirements of the user. The analyzer carries up to two different sensitivities of the detectors to allow highest precision for a variety of applications.

Main features

●Powerful software (multilingual, customized display, export of results)

●Low maintenance

●Robust design allows usage in production control and laboratory

●Easy calibration with standard materials or gas dose

●Hydrogen determination with heat extraction technique for determination of residual hydrogen

●High-capacity thermal conductivity cell

●Precise measurements even for low concentrations

●For samples of up to 10 g and 0.8 x 6 cm size

Standard Certification

For many applications (e.g. hydrogen determination in special alloys) no international standard is released. To assure a reliable and safe analysis the ELTRA application laboratory in Haan provides free of charge test measurements and aplplication support. This support encompasses not only the H-500, but the full ELTRA product portfolio of TGA, ONH and CS measurement

Application

alloy, copper, steel, cast iron

Specification

Thermogravimetric Analyzer TGA Thermostep

Thermogravimetry is a standard method to analyze organic, inorganic and synthetic materials. Thermogravimetric analysis in general means the measurement of the weight loss during a user-defined temperature or heating process.

Main features

●Measurement of up to 19 samples in one analysis

●Sample weights of up to 5 g

●Fast heating rates, accurate temperature control

●High-performance, precise weighing cell

●Automatic placing and lifting of crucible covers

●Robust design allows for use in laboratories and production

Standard Certification

The Environmental Inspection Institute of the Environmental Protection Agency of the Executive Yuan announced the detection of SRF:

Eltra TGA complies with the detection method of ash and combustible content in solid renewable fuels

Application

Due to the flexible application management the TGA Thermostep can measure TGA parameters in many samples like coal, coke, building materials, food …

Field of application:agriculture, biology, chemistry / plastics, coal / power plant, construction materials, environment / recycling, food, geology / mining, glass / ceramics, medicine / pharmaceuticals