Circuit board/ Robot/ Power repair and overhaul

Circuit board

Most circuit boards in semi-conductor equipment can be repaired without circuitry. Under carefully repaired, co-work with users to test it on their own equipment, there are about 80% successful rate.Truly, repaired is not difficult, its how to prevent same root cause happen again.

In Scientech, weve experienced engineers, systematization team work and continuing improved study in order to give our customer reliable service.

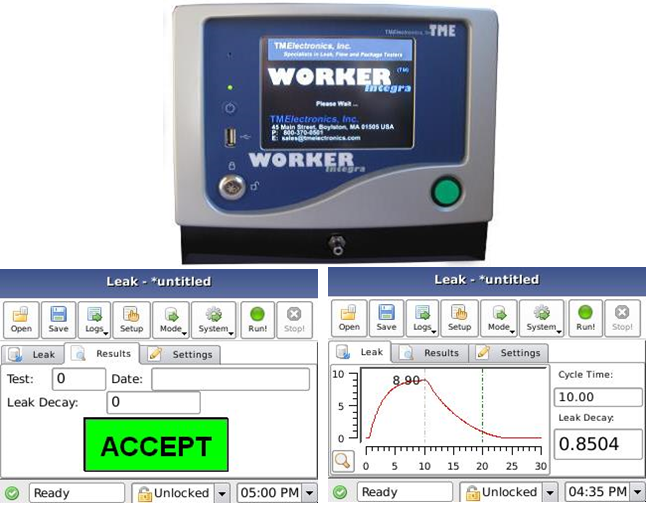

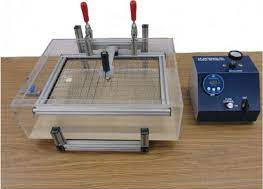

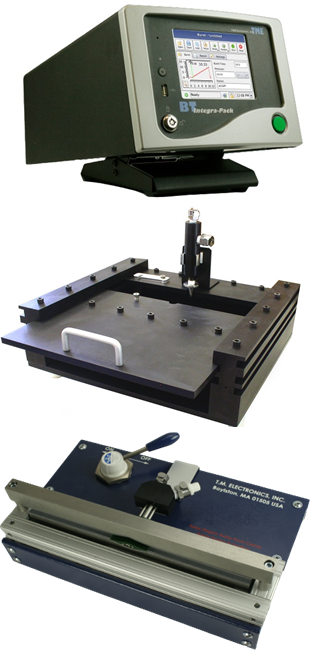

Scientech provides all kinds of suitable instrument tools without side effect such as PCB trouble shooter, In circuit Tester, BGA rework tool, capacitance tester, Power supply tester, High frequency constant temperature soldering iron, electric tin sucker, soldering pot, and microscope system, etc...

Under our professional repairing and service, your goods will optimize as a new one. Scientech appreciates to co-work with customers in any projects.For example: To modify and improve PCB abilities to reduce fail rate,and even to repair PCB which already out of production.

Key components repairing

Scientech supplies all kinds of the key components repairing. Even with the equipments we are not distributing, we also can collaboration and develop with customer.

Robot repairing

- Scientech represents Kensington. For Kensington robot sale and repair, please refer to : Kensington automation

- Scientech represents Nidec-Genmark. For Nidec-Genmark robot sale and repair, please refer to : Nidec-Genmark automation

Power repair and overhaul

- Scientech represents Dynatronix. For Dynatronix power sale and repair, please refer to : Dynatronix power

- Scientech represents Advanced Energy (AE). For AE power sale and repair, please refer to : Advanced Energy (AE)