Intlvac

Intlvac Thin Film provides PVD (Physical Vapor Deposition) and IBE (Ion Beam Etch) systems for magnetic materials, metals, and oxides. Our in-house development lab designs, engineers, and manufactures machinery and processes used for PVD and IBE. Intlvac Thin Film provide prototype and production-run coating services to customers around the world. Intlvac Thin Film provides customized engineering solutions. Intlvac Thin Film Advanced manufacturing leader in materials science and thin film technology.

Intlvac Nanochrome™ Pico Thin Film Deposition System

The Intlvac Nanochrome™ Pico is the ultimate all-purpose prototyping and R&D physical vapor deposition (PVD) platform on the market. It can be configured for a wide range of applications.

The NC Pico with its 16” D-shaped chamber and small footprint can fit into any lab and the modular design allows for easy process reconfiguration (ie. sputter up to sputter down). The NC Pico is also designed to incorporate a load-lock transfer from the atmosphere or between a pair of connected Pico chambers. Useful for systems dedicated to either metal films or oxides.

Main features

- small footprint

- modular design

- Incorporate a load-lock transfer from the atmosphere or between a pair of connected Pico chambers.

- Useful for systems dedicated to either metal films or oxides.

Standard Certification

Application

- It can be configured for a wide range of applications such as e-Beam evaporation for liftoff, optical interference filters, multi-layer barrier coatings, and transparent conductive oxides (TCOs)

Specification

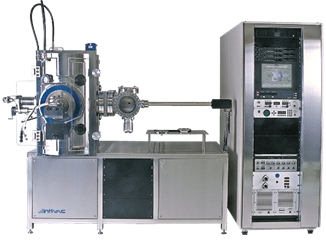

Nanochrome™ I R&D Load-Lock Thin Film Deposition System

Nanochrome™ I R&D Load-Lock system is capable of evaporating materials such as metals and dielectrics by Electron Beam Evaporation from a four or six pocket electron beam gun, onto a direct water cooled rotating substrate stage. Stepper motors allow automatic variable angle deposition as well.

The stage angle adjustment allows the system to be used for multi-layer electron beam evaporation, magnetron sputtering, and ion beam etching all during the same pump down cycle.

Main features

- Evaporate materials such as metals and dielectrics directly onto a water-cooled rotating substrate platform.

- Automatic variable angle deposition.

- The platform angle can be adjusted

Standard Certification

Application

- Multi-layer electron beam evaporation、 Magnetron sputtering, and ion beam etching.

Specification

Nanochrome™ II Thin Film Deposition System

The Nanochrome™ II is built around a vertical split “clam shell” design that has full access to the deposition area. The chamber stands as a vertical cylinder, nominal 32” I.D. and is 40” tall and is fabricated from 304L stainless steel. The chamber has a large variety of feed-throughs located on the top and bottom of the chamber, many of which are spares.

Finished inside and out to a high mechanical then electro polished to reduce surface area which reduces pump down time and water vapor backgrounds. The chamber has three Pyrex view ports, with glass cover slip in two positions. The deposition material is shielded from the windows and view ports that face the electron beam gun is fitted with a periscope and polorizing attenuator assemblies to allow viewing during deposition.

The top of the deposition chamber has a variety of feedthrough ports, we use a 2.0” hollow shaft ferrofluid type rotary, which has an optical window coupled to the top. The side and bottom of the chamber also have spare ports for future use.

Main features

- Vertical split "clam shell" design, can completely enter the deposition area

- Type cylinder made of 304L stainless steel

- Variety of feedthroughs on the top and bottom of the chamber

- Reduce pumping time and water vapor backgrounds

- Easy to observe during the deposition process

Standard Certification

Application

- The system is an ideal platform for long throw reactive sputtering, electron beam and thermal evaporation to produce high quality thin films.

Specification

NANOCHROME IV UV VIS - OPTICAL FILTER PRODUCTION SYSTEM

The Intlvac Nanochrome™ IV UV VIS ion assisted deposition system is Intlvac’s newest precision optical coating platform. The Nanochrome™ IV UV VIS system will make complex optical filters via ebeam evaporation with ion assist under optical control for real time re-optimization or via standard deposition controls.

Main features

- Exceptional process repeatability

- Baseline uniformity of 2%

- Automated process control

- Real time re-optimization

- 5-12" planets with dual-axis rotation

- temperature control up to 275º Celcius

Standard Certification

Application

- It can make complex optical filters

Specification